Designing the BART Car

|

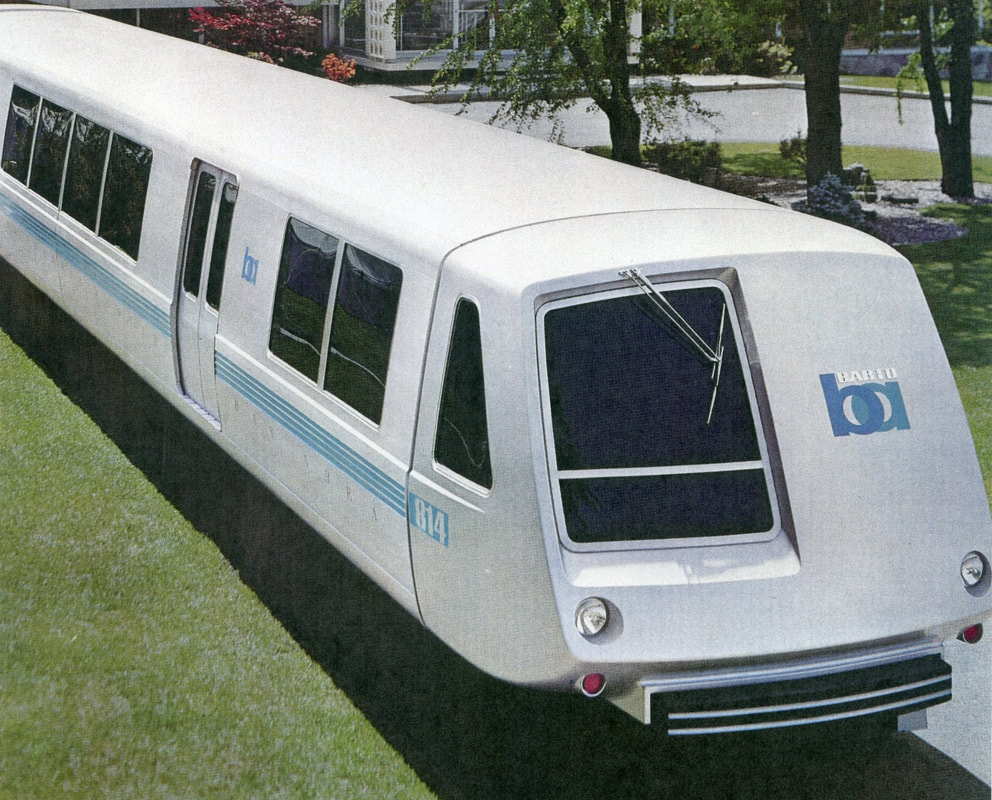

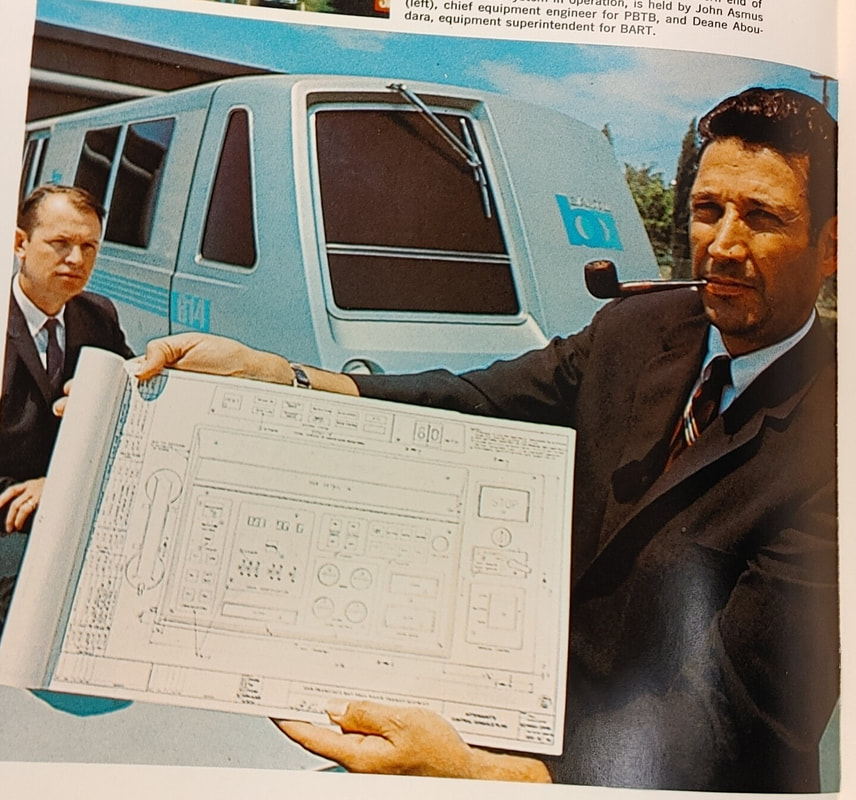

Starting with the overall objectives and constraints for the BART system, Sundberg-Ferar Industrial Design of Detroit, and St Louis Car Division of General Steel Industries of Granite City, IL, designed the aesthetic and human engineering aspects of the BART vehicle. The design of the mockup, undertaken by Sundberg-Ferar, was the product of many rounds of renderings, models, and collaboration with car builders. This cycle of collaboration between all parties allowed for a more seamless connection to the construction of the actual revenue cars. [1] The car itself was manufactured by W. Ashley Gray Jr. of St Louis Car Division of General Steel Industries, for a cost of $400,000.[2]

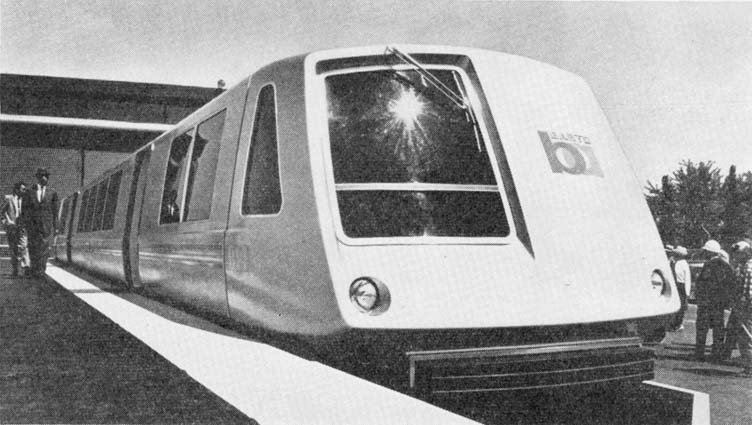

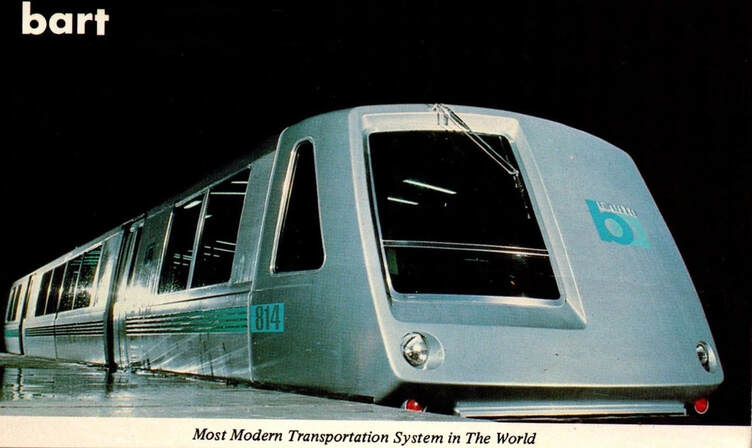

The mockup of the BART car was numbered 814 after the original district offices at 814 Mission Street, San Francisco. As noted during the unveiling of the car at the Diablo Test Track on June 22, 1964, the BART car was to represent the best of BART, and functions as a symbol of the entire BART project. As said by General Manager B.R. Stokes: This design car epitomizes more than anything else our goal of providing the most comfortable, fastest, safest and most economical means of interurban transportation the world has ever known. |

Our entire purpose in life, our only reason for existence, is to produce a system so inviting that Bay Area travelers will choose to ride the 80 mile-an-hour trains instead of adding to the traffic congestion that has had such an undesirable effect on our urban way of life…

The car we have unveiled here today is destined to establish an exciting new trend in rapid transit conveyances…This is not just a warmed over version of an existing commuter train. It's entirely new - the first in over a quarter of a century. There's nothing to compare it with for comfort and luxury, except possibly a jet airliner or the most expensive automobile.

Designer Carl Sundberg explained the design process of the car. The following is a transcription from his own words:

…Situated as we are in the heart of the automobile industry, our people are vitally aware of the importance of good vehicle design. We tried to employ the talent and knowledge we have gained here to produce for the Bay Area people a design that transcends anything yet conceived in the field. For us, it was labor of love.

We began the design process with the most essential ingredient, the human being, tailoring all elements to his or her needs. We knew, also, that the people of the Bay Area traditionally accept newness, that they do, in fact, hunger for innovation.

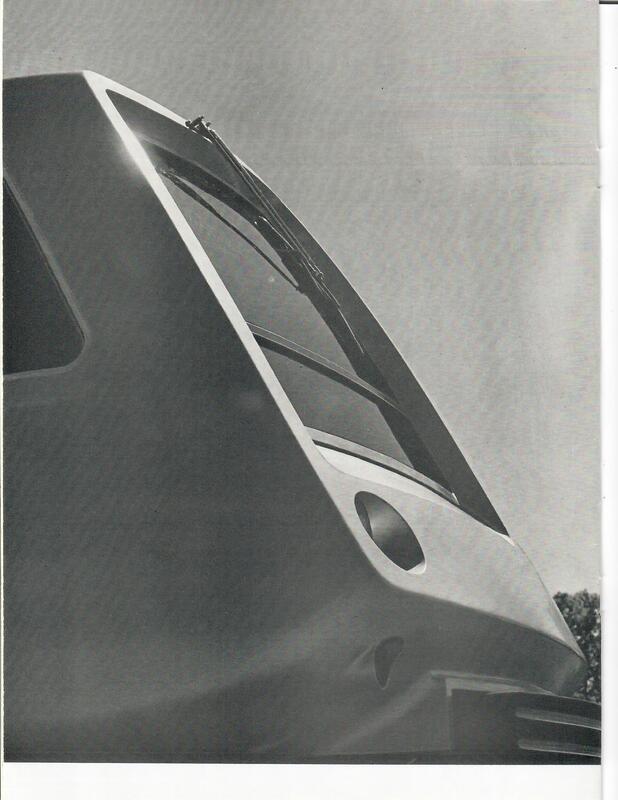

We gave the nose a sophisticated, sculptured look, yet we kept it simple; we used no gimmicks or clichés strictly for the sake of appearance. We wanted a modern vehicle, yet we stuck to the contention that a rapid transit train should look like a rapid transit train, and nothing else.

We wanted the car to appeal to all ages and walks of life, so we gave it a fleet look to reach the younger generation, yet a solid, practical, even dignified look to appeal to adults.

It was our purpose to make the interior of the car, as well as the exterior, competitive in design and comfort features with the most expensive automobile.

This, I feel, we have done. [3]

The 1.10 car mockup was displayed across the San Francisco Bay Area before the opening of the system. Hundreds of thousands of future riders provided their comments to help shape the human element of the BART railcar. The mockup also trekked down to Los Angeles, to help drum up support for a heavy rail system in their vicinity. In December 1971, car 814 was sold to Atlanta for the planned MARTA system, for a sum of $1,000.[4]

By May 1990, the 814 made its way to the Gold Coast Railroad Museum in Miami, Florida. It’s assumed to have been a victim of Hurricane Andrew in 1992.

On the technical side, the BART car was designed to be the most advanced rapid transit car ever built.

The automatic train control (ATC) system was designed to run trains at speeds up to 80 mph between stations, and bring them to a stop with the precision of plus or minus six inches. BART was the first rapid system to have the merging of multiple lines under ATC.

The car was built using extruded aluminum, contrasting to traditional sheet metal construction. These extruded aluminum pieces were combined to form a monocoque body shell. Although a rather new process for rail transit, these were proven techniques for the aerospace and aircraft industries.

All matters of truck design were considered as part of the Diablo Test Track project. By the time the revenue cars were built, the BART car was equipped with cast steel LFM-Rockwell inboard bearing trucks. The cars were equipped with automatically leveling air bag suspension, in addition to rubber bumpers, for a smooth ride.[5]

The high performance characteristics of BART required a new propulsion system. Taking advantage of recent developments in chopper control and increases in thyristor ratings, the BART car became the first rapid transit car to employ such a system. Hydraulic disk braking was used on the cars, an offshoot of the technology developed for off-highway trucks and aircraft landing gear.

Together, the carbody, sans undercar equipment, weighed about 200 pounds per linear foot. The cab-equipped A car, with all equipment and empty of passengers, weighed approximately 59,000 pounds, while the cabless B car, similarly empty, weighed approximately 57,000 pounds. The respective weights per linear foot of car length (786.6 lb and 814.3 lb respectively) placed the BART cars as among the lightest rapid transit cars ever made.

|

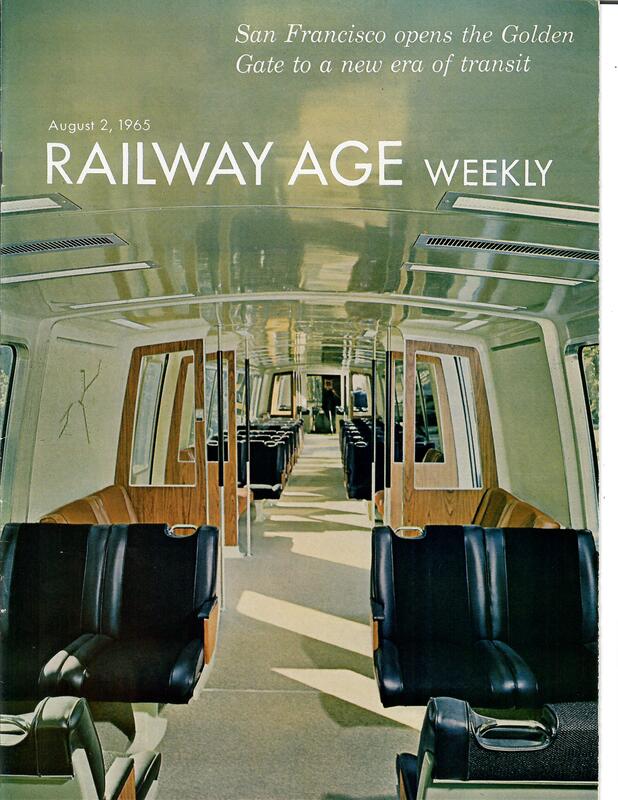

The interior was designed to be relatively comfortable, and early reports firmly state the importance of a clean and pleasing interior for “evening and Sunday trips - to the theater for example – and by ladies in midday for shopping, etc.” The BART car was to have a positive and dignified look, neither extravagant nor draconian, but realistic to both the requirements for the wear and tear related to the operation of a transit system and the goal of competing against the commuter automobile, including the factor of comfort. The large windows, air conditioning, end-to-end carpeting, 72 upholstered seats, modern lighting, and other features all contributed to the idea that the BART car was to be a “public asset and a source of pride.” In all, the design of the BART car combined both a desire to provide a comfortable and technologically advanced car in an attractive package. Certain aspects of the car would become industry standard, while other aspects were to be left as BART-only curiosities. BART cars were divided into two distinct car types – the A car and the B car. A cars had a sloped fiberglass cab, containing train control equipment and space for a “train attendant” (now called “train operator”). They were designed to be used as lead or trailing units in revenue service, and their aerodynamic shape also provides a pleasing appearance. The second type of BART car, the B car, resembled an A car, without a cab. They designed to be used only in the middle of trains during revenue service, but have hostling panels for manual operation in yards. |

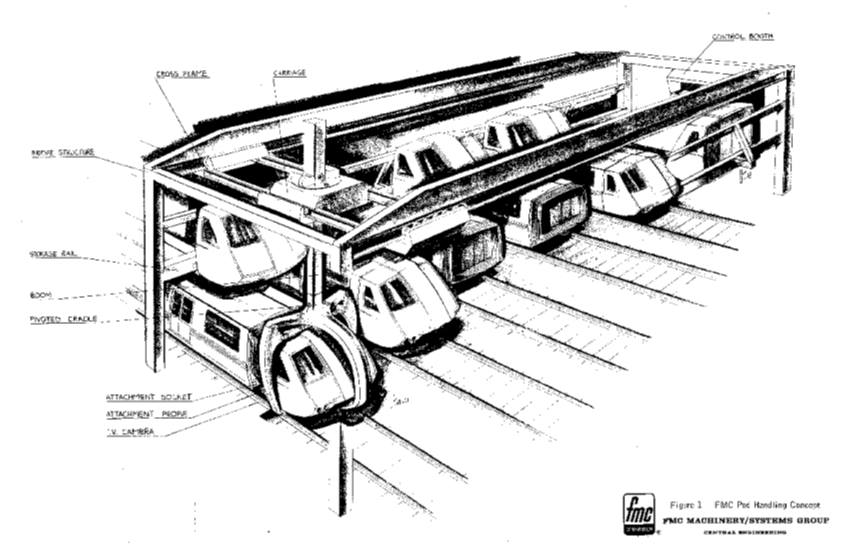

Early on, there was a serious consideration to have the cabs as detachable units, mounted on to a car in the yard as needed. In the most extreme case, this would mean that every car would be built as a B car, but with attachment hardware so it could become an A car for the day. This detachable pod concept was not chosen, particularly due to the large savings in having permanently mounted cabs on A cars, alongside the only real benefit of the detachable pod being traced to novelty[6]. However, the design of the A car, with a mounted fiberglass cab, would prove valuable for the A to B car conversions in the coming decades.

[1] Lawson, K.L, Chief Equipment Engineer. “Development of the BARTD Vehicle.” Parsons Brinkerhoff-Tudor-Bechtel. May 5, 1966. Western Railway Museum, Bay Area Electric Railway Museum Archives, DB# 177437

[2] Grieg, Michael. “BART’s Dream Car: Luxury Route for Commuters.” June 23, 1965. Collection of: BARTD General Rolling Stock News, Norman Therkelson Collection, Prelinger Library

[3] “Full-Scale Car for BARTD Is Unveiled” Passenger Transport, Volume 23, Number 12, New York, July 2, 1965. Pacific Bus Museum Collection

[4] Demoro, Harre W. “BART’s First Train Ends Work.” Oakland Tribune, December 1, 1971. Collection of: BARTD General Rolling Stock News, Norman Therkelson Collection, Prelinger Library

[5] [5] “National Historic Mechanical Engineering Landmark.” San Francisco Bay Area Rapid Transit System

The American Society of Mechanical Engineers International, 1997.

[6] “Train Consist Evaluation and Recommendation” Z949. March, 1967. PBTB

Further Reading

Contents:

1. Product: BART Commuter Rail Vehicle

2. Full-Scale Car For BARTD is Unveiled

3. Rohr: Background Information on the BART Rapid Transit Vehicle

4. BART Declared Historic Landmark: Vehicle Design Features

5. Why is BART wide gauge?

6. State of the Art Car (SOAC)

7. Railway Age Weekly (1965)

1. Product: BART Commuter Rail Vehicle

2. Full-Scale Car For BARTD is Unveiled

3. Rohr: Background Information on the BART Rapid Transit Vehicle

4. BART Declared Historic Landmark: Vehicle Design Features

5. Why is BART wide gauge?

6. State of the Art Car (SOAC)

7. Railway Age Weekly (1965)

Design of the BART Car

"Product: BART Commuter Rail Vehicle

Design Firm: Sundberg-Ferar, Southfield Michigan

Manufacturer: Rohr Corporation

Client: San Francisco Bay Area Rapid Transit District

The Bay Area Rapid Transit System has become a significant landmark of this region. It took the cooperation of many professions to implement this mass transportation system, and while it may not yet be working perfectly for everybody, it is an important example of a future-oriented and energy efficient mode of transportation. The train and vehicles were designed by an industrial design firm in Michigan, where most of our transportation design originates. The interior was designed with the passenger's need for comfort and a pleasant environment in mind. The soft focused lights, the uniform air circulation, comfortable seats and large windows as well as the easy accessibility for the disabled are just a few examples of these amenities. The exterior appearance of the train, designed more than ten years ago, is a clean and contemporary design. No wonder BART serves as a model for mass transportation design nationally and internationally."

Design Firm: Sundberg-Ferar, Southfield Michigan

Manufacturer: Rohr Corporation

Client: San Francisco Bay Area Rapid Transit District

The Bay Area Rapid Transit System has become a significant landmark of this region. It took the cooperation of many professions to implement this mass transportation system, and while it may not yet be working perfectly for everybody, it is an important example of a future-oriented and energy efficient mode of transportation. The train and vehicles were designed by an industrial design firm in Michigan, where most of our transportation design originates. The interior was designed with the passenger's need for comfort and a pleasant environment in mind. The soft focused lights, the uniform air circulation, comfortable seats and large windows as well as the easy accessibility for the disabled are just a few examples of these amenities. The exterior appearance of the train, designed more than ten years ago, is a clean and contemporary design. No wonder BART serves as a model for mass transportation design nationally and internationally."

Mockup 814

Passenger Transport, The Weekly Newspaper of the Transit Industry, Vol. 23, No 12, July 2, 1965

Full-Scale Car For BARTD is Unveiled

Special to Passenger Transport

Full-Scale Car For BARTD is Unveiled

Special to Passenger Transport

|

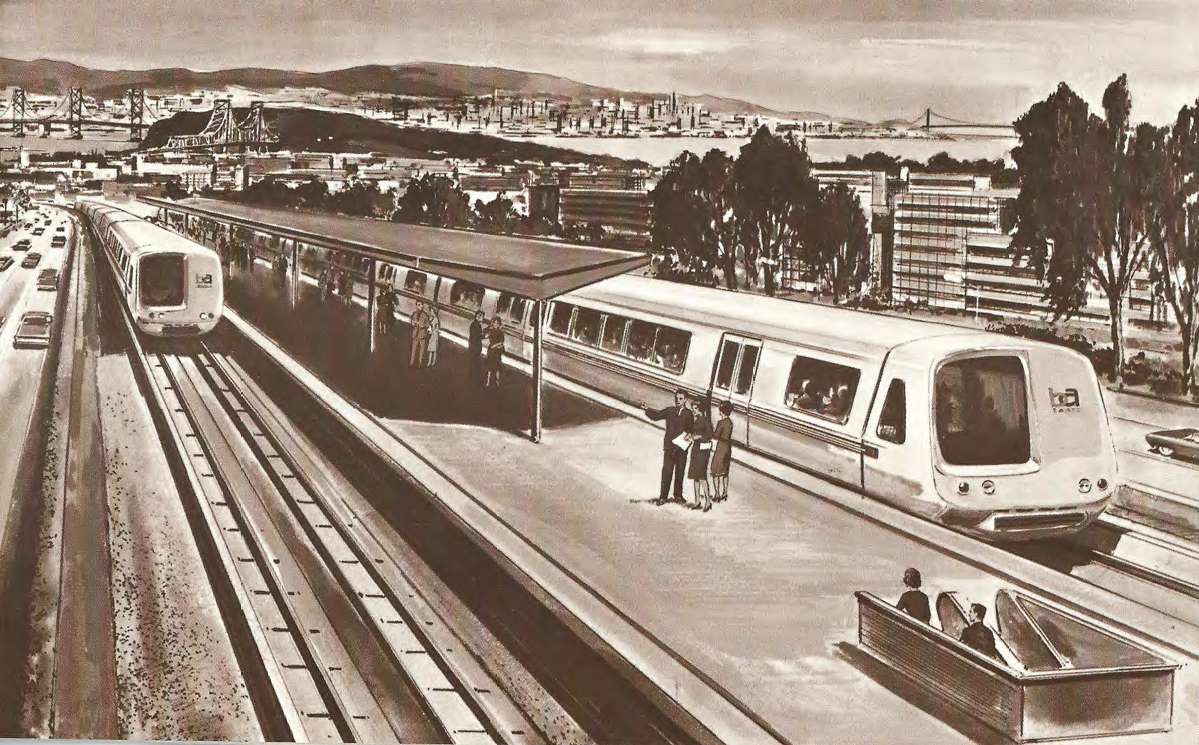

San Francisco – A modern rapid transit car for the Bay Area, styled to compete with the most luxurious automobile as a means of interurban travel, was unveiled by the Bay Area Rapid Transit District last week at ceremonies in Concord, Calif.

The car, presented by designed Carl. W. Sundberg to the District’s board of directors and the “people of the Bay Area,” is a full-scale model of the trains that will start carrying passengers in 1968. Mount on trailers, the prototype will be displayed during the next year in Concord, San Francisco, Oakland and possibly other communities with the District’s three metropolitan counties. |

“I predict that the BARTD car, along with other space-age concepts being designed into the Bay Area system, will completely revolutionize the transit industry in this country,” he said. “Certainly, the car we have unveiled here today is destined to establish an exciting new trend in rapid transit conveyances.”

“This is not just a warmed-over version of an existing commuter train. It’s entirely new – the first in over a quarter of a century. There’s nothing to compare it with for comfort and luxury, except possibly a jet airliner or the most expensive automobile.”

“This is not just a warmed-over version of an existing commuter train. It’s entirely new – the first in over a quarter of a century. There’s nothing to compare it with for comfort and luxury, except possibly a jet airliner or the most expensive automobile.”

|

The car was given its first Bay Area showing almost a year to the day after President Lyndon B. Johnson launched construction of the billion-dollar BARTD project, also at a ceremony in Concord (PT 6/26/64).

Other participants in the June 22nd unveiling ceremony held at BARTD’s Diablo Test and Research Center, where new transit ideas are being developed for the Bay Area system were: Adrien J. Falk, president of the BARTD Board of Directors; presidents of the two firms responsible for designing the car, Carl Sundberg of Sundberg-Ferar, Inc, Detroit, and W. Ashley Gray, Jr., General Steel Industries, Inc., Granite City, Illinois. St. Louis Car, a division of General Steel, was Sundbergs’s design partner. |

Stokes said: “This design car epitomizes more than anything else our goal of providing the most comfortable, fastest, safest and most economical means of interurban transport the world has ever known.

“Our entire purpose in life, our only reason for existence is to produce a system so inviting that Bay Area travelers will choose to ride the 80-mile-an-hour trains instead of adding to the traffic congestion that has led such an undesirable effect on our urban way of life.”

Sundberg, whose firm had designed everything from household appliances to pleasure boats, said he “found the BARTD assignment ideal from the point of view of a designer.”

“Situated as we are in the heart of the automobile industry, our people are vitally aware of the importance of good vehicle design. We tried to employ the talent and knowledge we have gained here to produce for Bay Area people a design that transcends anything yet conceived in the field. For us, it was a labor of love.

"We began the design process with the most essential ingredient, the human being, tailoring all elements to his or her needs. We knew, also, that the people of the Bay Area traditionally will accept newness, that they do, in fact, hunger for innovation.

“Situated as we are in the heart of the automobile industry, our people are vitally aware of the importance of good vehicle design. We tried to employ the talent and knowledge we have gained here to produce for Bay Area people a design that transcends anything yet conceived in the field. For us, it was a labor of love.

"We began the design process with the most essential ingredient, the human being, tailoring all elements to his or her needs. We knew, also, that the people of the Bay Area traditionally will accept newness, that they do, in fact, hunger for innovation.

|

"We gave the nose a sophisticated, sculptured look, yet we kept it simple; we used no gimmicks or clichés strictly for the sake of appearance. We wanted a modern vehicle, yet we stuck to the contention that a rapid transit train should look like a rapid transit train, and nothing else.

"We wanted the car to appeal to all ages and walks of life, so we gave it a fleet look to reach the younger generation, yet a solid, practical, even dignified look to appeal to adults." |

The interior of the car was designed specifically for the seated passenger, Sundberg said. He pointed out such features as:

"It was our purpose,” Sundberg said, “to make the interior of the car, as well as the exterior, competitive in design and comfort features with the most expensive automobile."

“This, I feel, we have done.”

After analyzing public rations to the various design elements incorporated in the mockup, BARTD engineers will prepare specifications and advertise fro competitive bids for construction of the first 450 vehicles.

The final BARD cars will be 70-feet long, 10 ½ fet wide and 10 ½ feet in height. Ceiling height will be 6 feet, 9 inches. Each car will have seats for 72 passengers.

The electric-powered vehicles, traveling on exclusive rights-of-way throughout the system, will reach speeds of 80 miles power hour, and average 45 to 50 miles an hour including station stops. The system will be entirely automatic, controlled from a central computer in Oakland, and capable of carrying 30,000 seated passengers an hour on a single line.

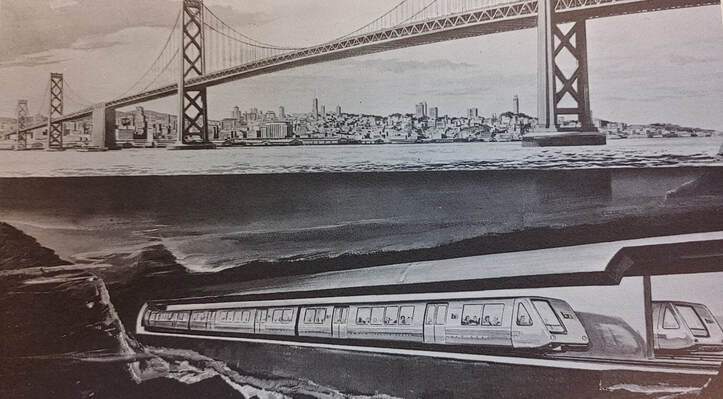

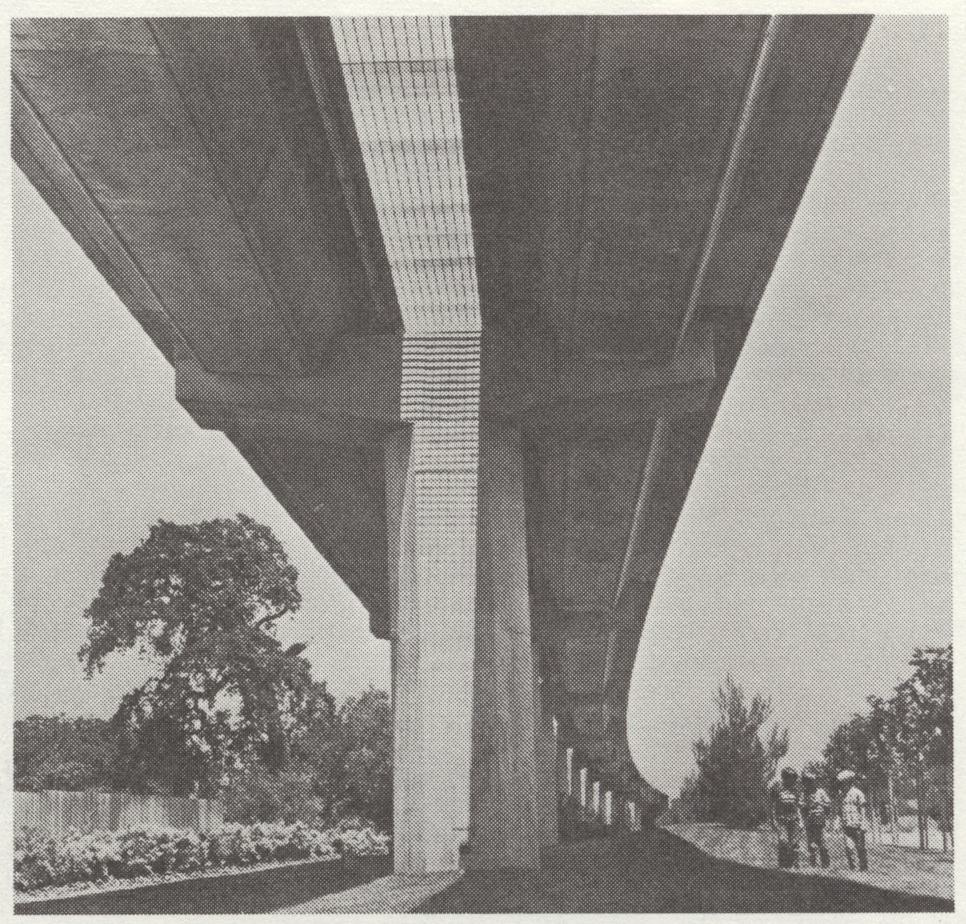

Seventy-five miles of lines will penetrate the three counties of Alameda, Contra Costa, and San Francisco, and will include 12 ½ miles of subways, 31 miles of aerial lines, 24 miles of surface lines, twin 3 ½ mile tunnels through the Berkeley Hills and a 4 mile tube under San Francisco Bay.

Most of the construction, which is well underway, is being financed by $792 million in general obligation bonds authorized by voters of the three counties in November, 1962, by a 61.2 per cent majority. Cost of the tube will be financed by $133 million in surplus bay bridge tolls, and the trains will be purchased with $71 million from revenue bonds.

The first line, between Richmond and Hayward, will open in 1968. The trans-bay line, from Concord, through Oakland and San Francisco to Daly City, will open in 1969, completing about 85 per cent of the system. The final extensions will open in 1970 and 1971.

- Comfortable upholstered seats with plenty of elbow room, comparable to those in a jet airlines, with an assist bar recessed within the seat profile;

- Soft, low-level lighting focused on the reading plane of each seat

- Silent air-conditioning which circulates fresh air and adapts to the different climatic environments the trains pass though;

- Large tinted-glass windows to shield passengers from the sun and provide a panoramic view of the Bay Area;

- Restful interior colors accented with wood grain paneling and brightly colored trim; and

- Carpeted floors.

"It was our purpose,” Sundberg said, “to make the interior of the car, as well as the exterior, competitive in design and comfort features with the most expensive automobile."

“This, I feel, we have done.”

After analyzing public rations to the various design elements incorporated in the mockup, BARTD engineers will prepare specifications and advertise fro competitive bids for construction of the first 450 vehicles.

The final BARD cars will be 70-feet long, 10 ½ fet wide and 10 ½ feet in height. Ceiling height will be 6 feet, 9 inches. Each car will have seats for 72 passengers.

The electric-powered vehicles, traveling on exclusive rights-of-way throughout the system, will reach speeds of 80 miles power hour, and average 45 to 50 miles an hour including station stops. The system will be entirely automatic, controlled from a central computer in Oakland, and capable of carrying 30,000 seated passengers an hour on a single line.

Seventy-five miles of lines will penetrate the three counties of Alameda, Contra Costa, and San Francisco, and will include 12 ½ miles of subways, 31 miles of aerial lines, 24 miles of surface lines, twin 3 ½ mile tunnels through the Berkeley Hills and a 4 mile tube under San Francisco Bay.

Most of the construction, which is well underway, is being financed by $792 million in general obligation bonds authorized by voters of the three counties in November, 1962, by a 61.2 per cent majority. Cost of the tube will be financed by $133 million in surplus bay bridge tolls, and the trains will be purchased with $71 million from revenue bonds.

The first line, between Richmond and Hayward, will open in 1968. The trans-bay line, from Concord, through Oakland and San Francisco to Daly City, will open in 1969, completing about 85 per cent of the system. The final extensions will open in 1970 and 1971.

(The mockup was numbered 814 after the original district offices located at 814 Mission Street, San Francisco)

BART Declared Historic Landmark: Vehicle Design Features

BART used aluminum extrusions—some the full 70-foot length of the car—to produce a fast, lightweight, and more energy-efficient vehicle.

The aluminum segments were constructed to produce a single unified car shape, in contrast to other systems requiring a separate heavy undercar support frame.

BART’s new “monocoque” shell design had never before been used in America for railroad cars. The whole body served as the frame, giving it dynamic resilience. The car shell was reinforced in key areas such as around door frames and at each truck location, where a “body bolster” strengthened the shell to accept the truck.

The new car design was 40% lighter than the average subway car weighing 1,200 lb. per linear foot. Clearly, at 700 lb./linear foot (totaling 59,000 lb.) BART cars required much less power to move—an important overall objective of the design program.

In fact, environmental concerns such as energy efficiency, protection of air quality, reduction of noise, and repair/maintenance issues remained preeminent considerations of the system’s designers.

The aluminum segments were constructed to produce a single unified car shape, in contrast to other systems requiring a separate heavy undercar support frame.

BART’s new “monocoque” shell design had never before been used in America for railroad cars. The whole body served as the frame, giving it dynamic resilience. The car shell was reinforced in key areas such as around door frames and at each truck location, where a “body bolster” strengthened the shell to accept the truck.

The new car design was 40% lighter than the average subway car weighing 1,200 lb. per linear foot. Clearly, at 700 lb./linear foot (totaling 59,000 lb.) BART cars required much less power to move—an important overall objective of the design program.

In fact, environmental concerns such as energy efficiency, protection of air quality, reduction of noise, and repair/maintenance issues remained preeminent considerations of the system’s designers.

Why is BART wide gauge?

BART uses a unique wider track gauge, at 5 feet 6 inches.

As per the PBTB April 1964 report "Assuring the Stability of the BARTD Rapid Transit Vehicle", wide gauge was chosen to ensure lateral stability and safety of the lightweight cars (~800 lb/ linear ft) while exposed to high wind conditions on a curve. A standard gauge, empty car standing on a superelevated curve with high crosswind would not have an adequate margin of stability. The same report also noted that this wide gauge would support the effort to build lightweight cars, which in turn, "would make possible the operating economies inherent in a lightweight rapid transit system" plus an increase in riding comfort.

The gauge chosen was shown to be the maximum gauge permitted without an exponential increase in construction costs.

Source: Parsons Brinckerhoff-Tudor-Bechtel, "Assuring the Stability of the BARTD Rapid Transit Vehicle" April 1964. Richard Townley Collection, Western Railway Museum archives.

As per the PBTB April 1964 report "Assuring the Stability of the BARTD Rapid Transit Vehicle", wide gauge was chosen to ensure lateral stability and safety of the lightweight cars (~800 lb/ linear ft) while exposed to high wind conditions on a curve. A standard gauge, empty car standing on a superelevated curve with high crosswind would not have an adequate margin of stability. The same report also noted that this wide gauge would support the effort to build lightweight cars, which in turn, "would make possible the operating economies inherent in a lightweight rapid transit system" plus an increase in riding comfort.

The gauge chosen was shown to be the maximum gauge permitted without an exponential increase in construction costs.

Source: Parsons Brinckerhoff-Tudor-Bechtel, "Assuring the Stability of the BARTD Rapid Transit Vehicle" April 1964. Richard Townley Collection, Western Railway Museum archives.

|

"A wide gauge, duorail system was chosen by the Bay Area Rapid Transit District as a result of a 1963 study by Parsons Brinckerhoff-Tudor-Bechtel, General Engineering Consultants to the San Francisco Bay Area Rapid Transit..." (pg 2198)

"Since a third of the BART system will be on aerial structure (Fig. 2) exposed to winds, it was decided to investigate the stability of such lightweight cars. For this purpose, Stanford Research Institute of Menlo Park conducted wind tunnel tests of a vehicle model. The findings contributed to the selection of 5 ft-6 in. gage as best suited to the conditions of the Bay Area. This compares with the 4 ft 8-1/2 in. which is standard gage for railroad service in the United States. Accommodation of the wider 5 ft-6 in. gage can be readily accomplished as the traction power contact rail already requires installation of longer ties. On the other hand, ex- tension beyond 5 ft-6 in. would demand wider subways and tunnels, at substantially higher construction cost" (pg 2198-2199). Source: Irvin, L. A. and J. R. Asmus. The Bay Area Rapid Transit Vehicle System. SAE Transactions, 1968, Vol. 77, Section 3: Papers 680436–680591 (1968), pp.2198-2199 |

Why can't other trains run on BART?

The following paragraphs are just a few notes on why any interchange on BART tracks would be inefficient, even if BART was standard gauge.

Outside of rail gauge, the following factors prevent other system's/railroad's trains from running on BART:

Technical:

Train control: BART uses a very unique train control system, which is incompatiable with mainline railroads. This is like most heavy rail/subway/metro systems, and virtually all heavy rail/subway/metros in the United States.

Scheduling: Headways can range from 30 minutes to less than 3 minutes throughout the system, during different times of the day. There is little to no "extra" time to fit in another passenger train without impacting the operation of a BART train. Also to consider, many conventional railroad cars are designed for longer station dwells (stops).

Weight: BART cars are very light (57,000 lbs on an original B car, 67,500 lbs on the heaviest D car). An amfleet weighs 106,000 – 113,000 lbs, nearly twice of a BART car. Add in a locomotive (ACS-64), and that's an additional 215,000 lbs. This would be certainly a danger on an aerial. This also factors into power consumption. Heavy conventional trains were never considered when the substations were built. They are designed to power lighter BART trains.

Size: BART cars are moderately long, but very squat. The 10'6" height can't fit most passenger cars, let alone anything taller than a shorter boxcar (in the tunnels).

Crashworthiness: BART is under CPUC/FRA jurisdiction, not FRA jurisdiction. Thus, rail transit cars have different standards for safety. It would not be wise to run heavy, stainless steel bilevel cars with light, aluminum bodied BART cars.

"It is established transit industry practice to design heavy rail cars (i.e., high platform) to 200,000-lb buff" (155).

"For trains weighing 600,000 lb tare (empty), buff strength per car of 400,000 lb was required. For a train of over 600,000 lb, buff strength of 800,000 lb was, and is, required. The regulation applies only to railroad M U cars" (155).

However, if BART was a Light Rail system, this may be a different case. It may be possible for a selection of light rail systems to moonlight as freight railroad tracks, such as San Diego which does/did.

Source:

Vigrass, J. William. Joint Use of Track by Electric Railways and Railroads: Historic View. Hill International, Inc. <https://onlinepubs.trb.org/Onlinepubs/conf/1995/cp8/cp8v1-017.pdf>

To see more details on FRA vs FTA jurisdiction, see the source below:

FRA Policy on Jurisdiction Over Light Rail Passenger Operations. International Association of Sheet Metal, Air, Rail and Transportation Workers. <https://smart-union.org/td/summaries-of-railroad-safety-laws/>

Political:

CPUC approval would be required to allow such an operation.

Outside of rail gauge, the following factors prevent other system's/railroad's trains from running on BART:

Technical:

Train control: BART uses a very unique train control system, which is incompatiable with mainline railroads. This is like most heavy rail/subway/metro systems, and virtually all heavy rail/subway/metros in the United States.

Scheduling: Headways can range from 30 minutes to less than 3 minutes throughout the system, during different times of the day. There is little to no "extra" time to fit in another passenger train without impacting the operation of a BART train. Also to consider, many conventional railroad cars are designed for longer station dwells (stops).

Weight: BART cars are very light (57,000 lbs on an original B car, 67,500 lbs on the heaviest D car). An amfleet weighs 106,000 – 113,000 lbs, nearly twice of a BART car. Add in a locomotive (ACS-64), and that's an additional 215,000 lbs. This would be certainly a danger on an aerial. This also factors into power consumption. Heavy conventional trains were never considered when the substations were built. They are designed to power lighter BART trains.

Size: BART cars are moderately long, but very squat. The 10'6" height can't fit most passenger cars, let alone anything taller than a shorter boxcar (in the tunnels).

Crashworthiness: BART is under CPUC/FRA jurisdiction, not FRA jurisdiction. Thus, rail transit cars have different standards for safety. It would not be wise to run heavy, stainless steel bilevel cars with light, aluminum bodied BART cars.

"It is established transit industry practice to design heavy rail cars (i.e., high platform) to 200,000-lb buff" (155).

"For trains weighing 600,000 lb tare (empty), buff strength per car of 400,000 lb was required. For a train of over 600,000 lb, buff strength of 800,000 lb was, and is, required. The regulation applies only to railroad M U cars" (155).

However, if BART was a Light Rail system, this may be a different case. It may be possible for a selection of light rail systems to moonlight as freight railroad tracks, such as San Diego which does/did.

Source:

Vigrass, J. William. Joint Use of Track by Electric Railways and Railroads: Historic View. Hill International, Inc. <https://onlinepubs.trb.org/Onlinepubs/conf/1995/cp8/cp8v1-017.pdf>

To see more details on FRA vs FTA jurisdiction, see the source below:

FRA Policy on Jurisdiction Over Light Rail Passenger Operations. International Association of Sheet Metal, Air, Rail and Transportation Workers. <https://smart-union.org/td/summaries-of-railroad-safety-laws/>

Political:

CPUC approval would be required to allow such an operation.

6. State of the Art Car (SOAC)

Although the State of the Art Car (SOAC) project was not part of the BART project, BART heavily influenced the design of SOAC, as seen in the NTSB-RAR-74-2 "Collision of the State-of-the-Art Transit Cars with a Standing Car, High Speed Ground Test Center Pueblo, Colorado August 11, 1973" report:

Vehicles

Design concepts for the SOAC. Primary goals of the SOAC were to be passenger convenience and operating efficiency. The overall objective of the project, as set forth by UMTA, was to enhance the attractiveness of rail transportation to urban travelers by providing service that is as comfortable, reliable, safe, and economical as possible.

Specifications for the SOAC were based on Boeing Vertol's evaluation of currently available transit cars and subsystems. UMTA designated "state of the art" as that which was used on the Bay Area Rapid Transit (BART) system. Accordingly, a document, Detail Specification for State-of-the-Art Car, was prepared and released to the public. The specification follows the format of Guideline Specification for Urban Rail Cars, a document previously prepared for UMTA. Some paragraph numbers from the latter document were indicated as "not applicable" or "not specified" in the specification for the SOAC. A paragraph was "not specified", if the item to which it referred had not been called for in Boeing Vertol's contract with UMTA. In the final specification, crashworthiness criteria, certain reliability data, system safety data, and value and human-factor engineering data were classified as "not specified."

Design concepts for the SOAC. Primary goals of the SOAC were to be passenger convenience and operating efficiency. The overall objective of the project, as set forth by UMTA, was to enhance the attractiveness of rail transportation to urban travelers by providing service that is as comfortable, reliable, safe, and economical as possible.

Specifications for the SOAC were based on Boeing Vertol's evaluation of currently available transit cars and subsystems. UMTA designated "state of the art" as that which was used on the Bay Area Rapid Transit (BART) system. Accordingly, a document, Detail Specification for State-of-the-Art Car, was prepared and released to the public. The specification follows the format of Guideline Specification for Urban Rail Cars, a document previously prepared for UMTA. Some paragraph numbers from the latter document were indicated as "not applicable" or "not specified" in the specification for the SOAC. A paragraph was "not specified", if the item to which it referred had not been called for in Boeing Vertol's contract with UMTA. In the final specification, crashworthiness criteria, certain reliability data, system safety data, and value and human-factor engineering data were classified as "not specified."

7. Railway Age Weekly (1965)

9/15/22, 10/22/22