Background

By the mid-late 1970s, it was apparent that BART needed more B cars, and that BART required more time to change train lengths than desireable. The former problem was addressed with the A to B car (800 series) program, while the latter required an entirely new car design, the C car. The original order C cars, named the C1 cars, rolled in service for over 35 years, from March 28, 1988 to May 15, 2023.

|

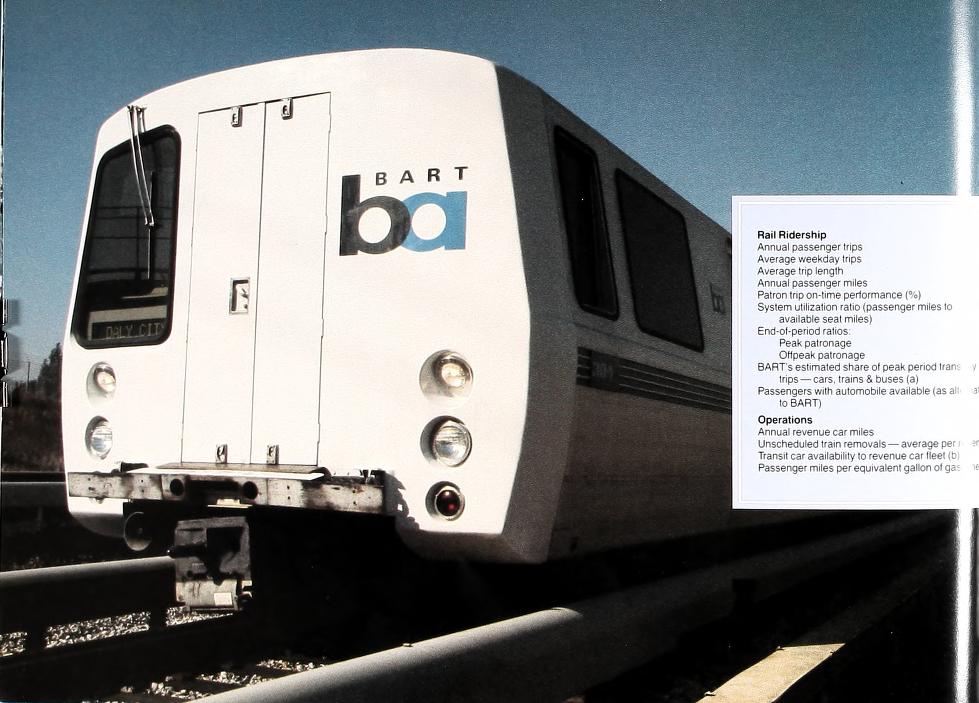

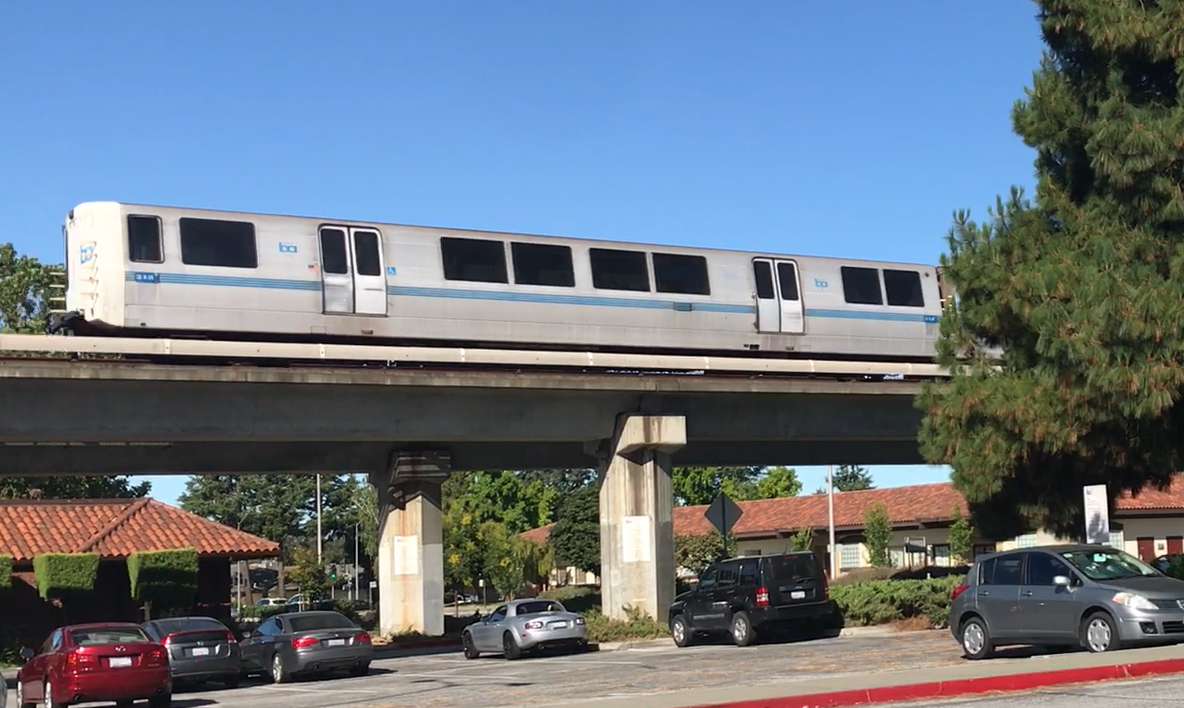

The C car design allowed for these cars to be used as lead, trailing, or mid cars. This was contrasted to the original Rohr built fleet of A and B cars, of which were only to be used in lead/trailing and midtrain position respectively.

C cars allowed for train resizing (makes/breaks) outside of yards. Traditionally, long trains ran in the commute periods and short trains ran during off peak periods. Before C cars, trains had to return to the yard to add or remove B cars, resulting in additional time and operator requirements. With C cars, trains can be lengthened (a procedure called a "make") while at the station platform, and can be shortened by uncoupling 2 C cars, splitting a train into two pieces (a procedure called a "break"). This type of operation allowed for greater flexibility in train sizes. To note, unlike the original A cars, the cab of the C cars is integral to the carbody (made of aluminum), and the Y end is painted white as a nod to the A car design. |

|

The contract in October 1982 was originally at $180 Million (44 million less than the only US Bidder, Budd), however it was increased to $228-241.5 million by 1985-1987. At the time, they were the world's most expensive transit units.

|

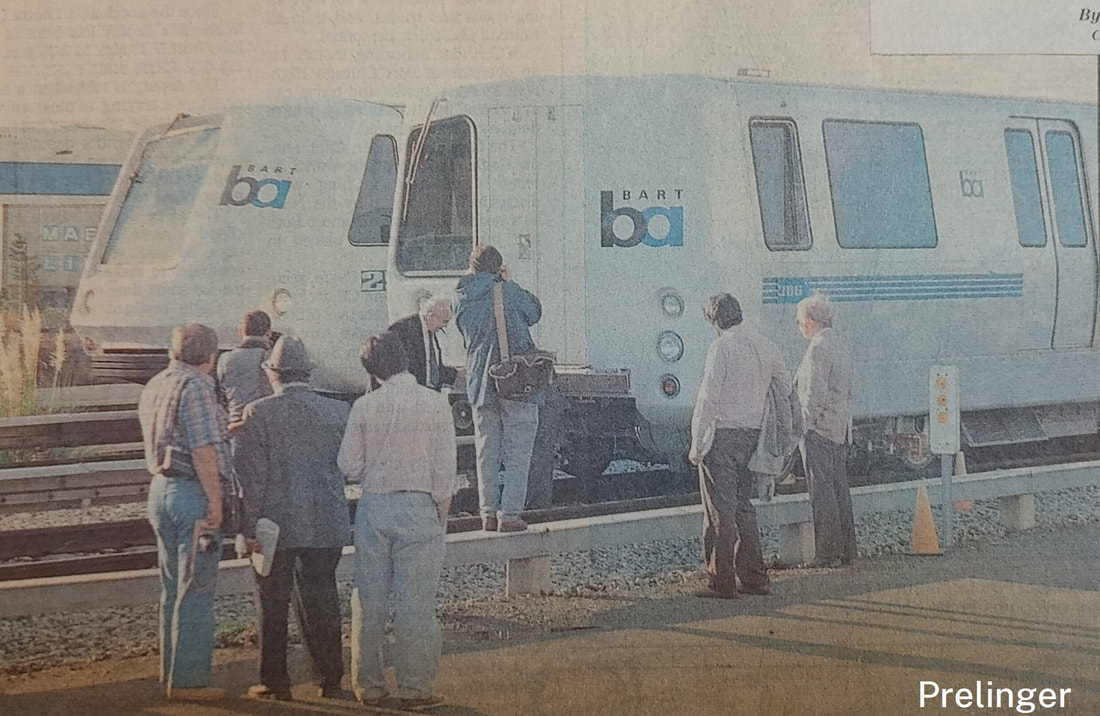

The first 4 C cars, 301-304(1st) were all prototypes used to test/burn-in the C car design. They were built in 1985.

After testing, they were scrapped (reasons include unacceptable carbody quality). They were replaced with production cars in the late 1980s, of the same fleet number.

Production cars, 301-304 (2nd), and 305-450 were assembled between 1987 and 1989 at 3377 Western Avenue, Union City, CA.

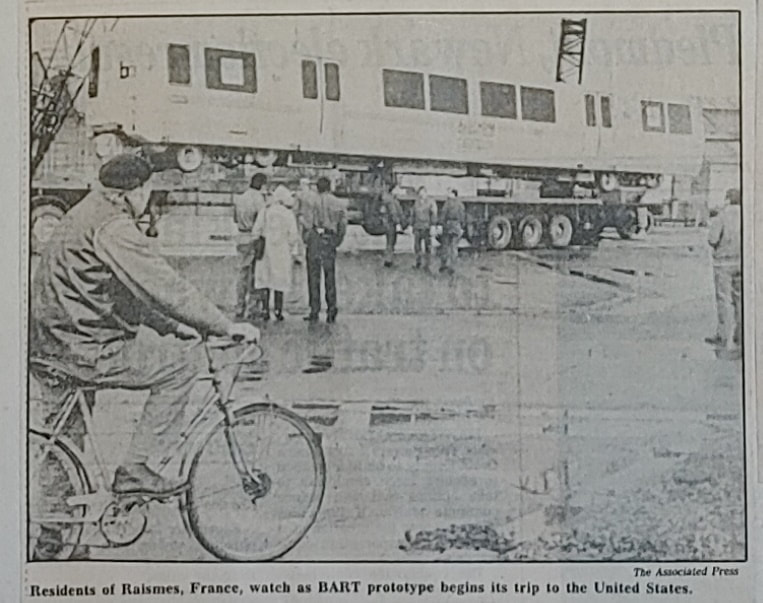

Carbodies were welded in Raismes, France, but final assembly occured in Union City. About 2/3 of the car was US made/assembled, including Westinghouse traction package and Knorr dynamic brakes. They entered service over the course of multiple years, 1987/1988 - 1990.

Before the C2 cars, the C1 cars were originally known as C cars. In the later years, the Alstom C1 and Morrison Knudsen C2 cars were together as known C cars. Occasionally though, C1 cars will be referred to as "C cars" while the C2s will be referred to as "C2 cars" (in the same sentence). This website tends to use "C1 cars" to refer to only C1 cars, and "C cars" to refer to all C1 and C2 cars.

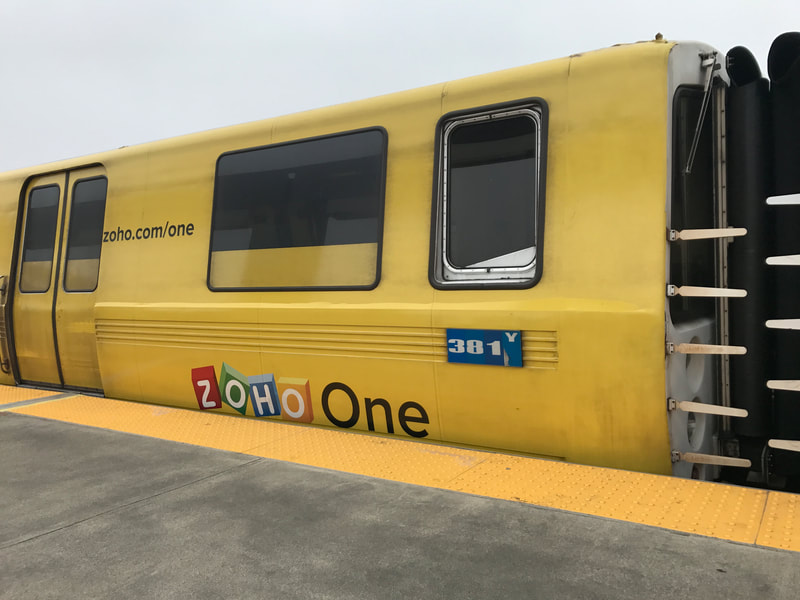

Quite a few C1 cars had ad wraps. See the Ad Wraps page to view more about these colorful BART cars.

In June 2020, during the early COVID-related service cuts, about 1/3 (50) of the roughly 150 remaining cars were left in service. Numbers increased back to 90 cars in December 2021. In September 2022, 40 C1 cars were available for revenue service, including those undergoing periodic shops. About 21 C1 cars were out on weekdays and over 90 C1 cars have been scrapped.

The final 24 C1 cars were decomissioned and stored, to be scrapped/preserved, in May 2023. No C1 cars roll in service. One C1 car (329) will be preserved at the Western Railway Museum in 2024, and one other (323) is used as a fire training car for a local fire department. All other C cars were scrapped.

After testing, they were scrapped (reasons include unacceptable carbody quality). They were replaced with production cars in the late 1980s, of the same fleet number.

Production cars, 301-304 (2nd), and 305-450 were assembled between 1987 and 1989 at 3377 Western Avenue, Union City, CA.

Carbodies were welded in Raismes, France, but final assembly occured in Union City. About 2/3 of the car was US made/assembled, including Westinghouse traction package and Knorr dynamic brakes. They entered service over the course of multiple years, 1987/1988 - 1990.

Before the C2 cars, the C1 cars were originally known as C cars. In the later years, the Alstom C1 and Morrison Knudsen C2 cars were together as known C cars. Occasionally though, C1 cars will be referred to as "C cars" while the C2s will be referred to as "C2 cars" (in the same sentence). This website tends to use "C1 cars" to refer to only C1 cars, and "C cars" to refer to all C1 and C2 cars.

Quite a few C1 cars had ad wraps. See the Ad Wraps page to view more about these colorful BART cars.

In June 2020, during the early COVID-related service cuts, about 1/3 (50) of the roughly 150 remaining cars were left in service. Numbers increased back to 90 cars in December 2021. In September 2022, 40 C1 cars were available for revenue service, including those undergoing periodic shops. About 21 C1 cars were out on weekdays and over 90 C1 cars have been scrapped.

The final 24 C1 cars were decomissioned and stored, to be scrapped/preserved, in May 2023. No C1 cars roll in service. One C1 car (329) will be preserved at the Western Railway Museum in 2024, and one other (323) is used as a fire training car for a local fire department. All other C cars were scrapped.

|

With their chopper control, it was hard to mistake the sound of a C car propelling itself out of the station (the steady buzz/hum of the chopper control system and brushing sound of the traction motors).

|

|

General Details

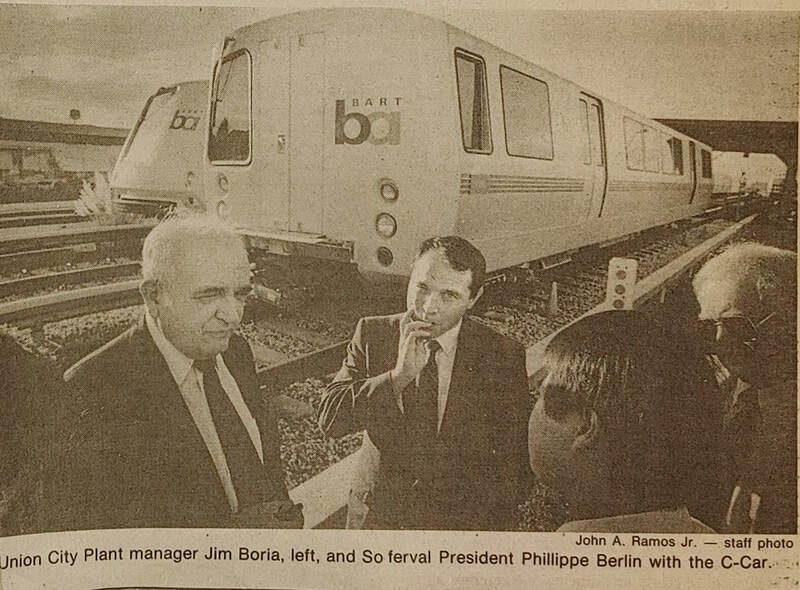

Builder: Alsthom/Soferval (now known as Alstom)

Original Assembly Location: Raismes, France (Prototypes), Union City, CA (Production cars)

Years of Construction: 1985 (Prototypes), 1987-1990 (Production cars)

Quantity: 150

Length: 70 feet

Weight (Empty): 63,500 lbs

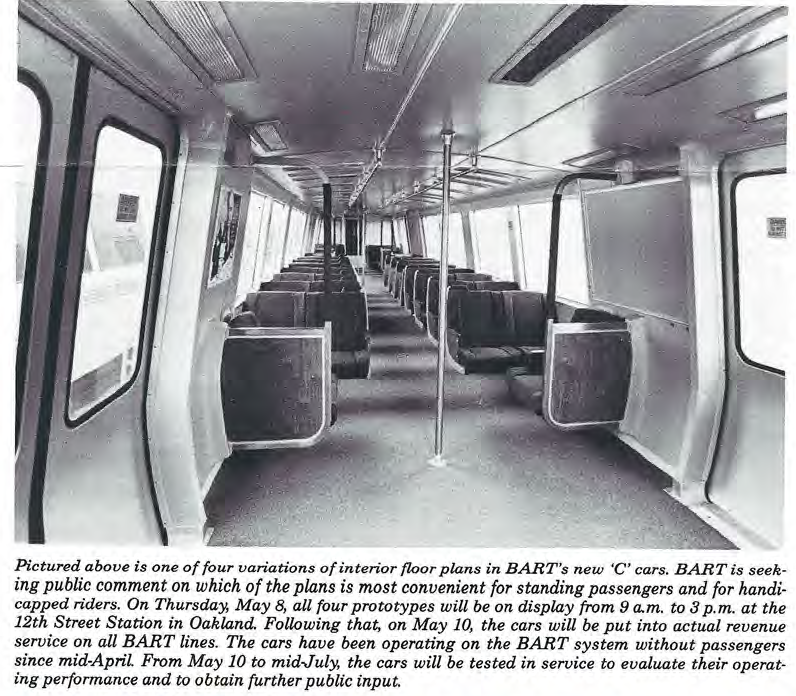

Seats: 64 (Original), 56 (Current)

Propulsion: Westinghouse DC Chopper drive with 4 x 150 HP Westinghouse Model 1463 motors (motors built under subcontract in Manchester, England by GEC). Essentially the same motors as the original A and B cars.

Brakes: Knorr dynamic/regenerative to 3 mph, Hydraulic friction braking below 3 mph.

Auxiliary Power Supply Equipment (APSE): Bombardier

HVAC: Wabco, 14 ton

Truck: Fabricated Steel (welded steel plate)

Electronic Horn: Federal Signal

Coupler: Wabco N3

Preventative Maintenance: Every 600 hours

Cost: $228 Million

Avg mileage (May 2023, lifetime): 2.84 Million miles

Original Assembly Location: Raismes, France (Prototypes), Union City, CA (Production cars)

Years of Construction: 1985 (Prototypes), 1987-1990 (Production cars)

Quantity: 150

Length: 70 feet

Weight (Empty): 63,500 lbs

Seats: 64 (Original), 56 (Current)

Propulsion: Westinghouse DC Chopper drive with 4 x 150 HP Westinghouse Model 1463 motors (motors built under subcontract in Manchester, England by GEC). Essentially the same motors as the original A and B cars.

Brakes: Knorr dynamic/regenerative to 3 mph, Hydraulic friction braking below 3 mph.

Auxiliary Power Supply Equipment (APSE): Bombardier

HVAC: Wabco, 14 ton

Truck: Fabricated Steel (welded steel plate)

Electronic Horn: Federal Signal

Coupler: Wabco N3

Preventative Maintenance: Every 600 hours

Cost: $228 Million

Avg mileage (May 2023, lifetime): 2.84 Million miles

Construction

Click on each photo to view the full size image.

These photos were part of an incredible donation of C1 construction pictures. Thanks!

These photos were part of an incredible donation of C1 construction pictures. Thanks!

The C1 carbody was designed and manufactured from extruded aluminum pieces designed and built by Alusuisse of Switzerland. These pieces were welded together in Raismes, Valenciennes, France. The plant was owned by Société Franco-Belge in years prior, which merged into Alstom in 1982. The same plant was used to build the CQ310 carbodies of the MARTA system. The carbodies were shipped from France to the Port of Oakland, but soon after the voyages ended in Houston due to legal reasons.

Final assembly of the C cars was at 3377 Western Avenue, Union City, CA. The building was formerly used by the Soule Steel Company.

AEG-Westinghouse supplied the HVAC, brakes, propulsion, and ATC systems on the cars. The C car motors were built in Manchester, England, under subcontract to GEC. They were identical to the Westinghouse model 1463 (used on the A and B cars).

Final assembly of the C cars was at 3377 Western Avenue, Union City, CA. The building was formerly used by the Soule Steel Company.

AEG-Westinghouse supplied the HVAC, brakes, propulsion, and ATC systems on the cars. The C car motors were built in Manchester, England, under subcontract to GEC. They were identical to the Westinghouse model 1463 (used on the A and B cars).

301-304 (1st) - Prototypes

The first 4 C cars, 301-304(1st) were all prototypes used to test/burn-in the C car design. They were built in 1985.

After testing, they were scrapped (in fact, the carbodies were already rejected by BART due to quality concerns). They were replaced with production cars in the late 1980s, of the same fleet number.

Click on each photo to view the full size image.

After testing, they were scrapped (in fact, the carbodies were already rejected by BART due to quality concerns). They were replaced with production cars in the late 1980s, of the same fleet number.

Click on each photo to view the full size image.

Production Cars

Click on each photo to view the full size image.

All details subject to change due to legacy fleet decommissioning process.

5/16/23 Update - There are no C cars (C1 or C2) left in service.

6/15/23 Update - The final C1 scrapping was 6/15/23, leaving 323 (Hayward Fire Dept. Trainer) and 329 (Western Railway Museum) as the final C cars in existence.

All details subject to change due to legacy fleet decommissioning process.

5/16/23 Update - There are no C cars (C1 or C2) left in service.

6/15/23 Update - The final C1 scrapping was 6/15/23, leaving 323 (Hayward Fire Dept. Trainer) and 329 (Western Railway Museum) as the final C cars in existence.

301-325

301 - (Scrapped) Regional Measure 2 Demonstration Car.

302 - (Scrapped) Lead car in Inaugural Run of the C car, 3/28/1988 Fremont-Daly City.

303 - (Scrapped) Had a dent from a collision in a yard. Regional Measure 2 Demonstration Car.

304 - (Scrapped) Car number seen in Predator 2

305 - (Scrapped) Ex Zoho One Ad wrap, Fox, and Alaska Airlines.

306 - (Scrapped) First production C1 car, final assembly in Union City. Regional Measure 2 Demonstration Car.

307 - (Scrapped)

308 - (Scrapped)

309 - (Scrapped) Regional Measure 2 Demonstration Car.

310 - (Scrapped)

311 - (Scrapped) One of final 2 dozen C1 cars. Active until 5/23. Missing all exterior car number plates 4/23.

312 - (Scrapped) Regional Measure 2 Demonstration Car.

313 - (Scrapped)

314 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23. Ex Zoho One Ad wrap. Regional Measure 2 Demonstration Car.

315 - (Scrapped) Zoho One Ad wrap. Regional Measure 2 Demonstration Car.

316 - (Scrapped) Major damage to X end in Dec 17, 92 derailment. Missing end cap on X right end.

317 - (Scrapped)

318 - (Scrapped) Regional Measure 2 Demonstration Car.

319 - (Scrapped) Regional Measure 2 Demonstration Car.

320 - (Scrapped) Regional Measure 2 Demonstration Car.

321 - (Scrapped) Regional Measure 2 Demonstration Car.

322 - (Scrapped)

323 - (Retired) Now serves as Hayward Fire Department trainer on Winton Ave, next to Hayward Airport - 12/22.

324 - (Scrapped) Regional Measure 2 Demonstration Car.

325 - (Scrapped) Regional Measure 2 Demonstration Car.

302 - (Scrapped) Lead car in Inaugural Run of the C car, 3/28/1988 Fremont-Daly City.

303 - (Scrapped) Had a dent from a collision in a yard. Regional Measure 2 Demonstration Car.

304 - (Scrapped) Car number seen in Predator 2

305 - (Scrapped) Ex Zoho One Ad wrap, Fox, and Alaska Airlines.

306 - (Scrapped) First production C1 car, final assembly in Union City. Regional Measure 2 Demonstration Car.

307 - (Scrapped)

308 - (Scrapped)

309 - (Scrapped) Regional Measure 2 Demonstration Car.

310 - (Scrapped)

311 - (Scrapped) One of final 2 dozen C1 cars. Active until 5/23. Missing all exterior car number plates 4/23.

312 - (Scrapped) Regional Measure 2 Demonstration Car.

313 - (Scrapped)

314 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23. Ex Zoho One Ad wrap. Regional Measure 2 Demonstration Car.

315 - (Scrapped) Zoho One Ad wrap. Regional Measure 2 Demonstration Car.

316 - (Scrapped) Major damage to X end in Dec 17, 92 derailment. Missing end cap on X right end.

317 - (Scrapped)

318 - (Scrapped) Regional Measure 2 Demonstration Car.

319 - (Scrapped) Regional Measure 2 Demonstration Car.

320 - (Scrapped) Regional Measure 2 Demonstration Car.

321 - (Scrapped) Regional Measure 2 Demonstration Car.

322 - (Scrapped)

323 - (Retired) Now serves as Hayward Fire Department trainer on Winton Ave, next to Hayward Airport - 12/22.

324 - (Scrapped) Regional Measure 2 Demonstration Car.

325 - (Scrapped) Regional Measure 2 Demonstration Car.

326-350

326 - (Scrapped)

327 - (Scrapped) Damaged in yard accident in 2010s, stored c. 2018-2019. Repaired and re-entered service in 2020. Regional Measure 2 Demonstration Car.

328 - (Scrapped) One of final 2 dozen C1 cars. Active until 5/23.

329 - To be preserved at Western Railway Museum. One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car. Last C car on BART property.

330 - (Scrapped)

331 - (Scrapped)

332 - (Scrapped)

333 - (Scrapped) Dirty car, due to ad residue

334 - (Scrapped) One of final 2 dozen C1 cars. Active as of 1/23 Regional Measure 2 Demonstration Car.

335 - (Scrapped) Regional Measure 2 Demonstration Car.

336 - (Scrapped) Regional Measure 2 Demonstration Car.

337 - (Scrapped) Regional Measure 2 Demonstration Car.

338 - (Scrapped)

339 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23.

340 - (Scrapped)

341 - (Scrapped) Regional Measure 2 Demonstration Car.

342 - (Scrapped)

343 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23. Dirty car, due to ad residue from previous Zoho One Ad wrap. Missing Y right side car number plate

344 - (Scrapped) Regional Measure 2 Demonstration Car.

345 - (Scrapped) CB1 car

346 - (Scrapped)

347 - (Scrapped)

348 - (Scrapped) Ex Zoho One Ad wrap.

349 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car - sticker remained until car was scrapped.

350 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car.

327 - (Scrapped) Damaged in yard accident in 2010s, stored c. 2018-2019. Repaired and re-entered service in 2020. Regional Measure 2 Demonstration Car.

328 - (Scrapped) One of final 2 dozen C1 cars. Active until 5/23.

329 - To be preserved at Western Railway Museum. One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car. Last C car on BART property.

330 - (Scrapped)

331 - (Scrapped)

332 - (Scrapped)

333 - (Scrapped) Dirty car, due to ad residue

334 - (Scrapped) One of final 2 dozen C1 cars. Active as of 1/23 Regional Measure 2 Demonstration Car.

335 - (Scrapped) Regional Measure 2 Demonstration Car.

336 - (Scrapped) Regional Measure 2 Demonstration Car.

337 - (Scrapped) Regional Measure 2 Demonstration Car.

338 - (Scrapped)

339 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23.

340 - (Scrapped)

341 - (Scrapped) Regional Measure 2 Demonstration Car.

342 - (Scrapped)

343 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23. Dirty car, due to ad residue from previous Zoho One Ad wrap. Missing Y right side car number plate

344 - (Scrapped) Regional Measure 2 Demonstration Car.

345 - (Scrapped) CB1 car

346 - (Scrapped)

347 - (Scrapped)

348 - (Scrapped) Ex Zoho One Ad wrap.

349 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car - sticker remained until car was scrapped.

350 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car.

351-375

351 - (Scrapped)

352 - (Scrapped) Ex Zoho One Ad wrap. Regional Measure 2 Demonstration Car.

353 - (Scrapped)

354 - (Scrapped) One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car.

355 - (Scrapped)

356 - "Burrito Bob" incident car. Not listed on roster 5/23

357 - (Scrapped).One of final 2 dozen C1 cars.

358 - (Scrapped)

359 - (Scrapped)

360 - (Scrapped) Regional Measure 2 Demonstration Car.

361 - (Scrapped). One of final 2 dozen C1 cars. Active through 5/23. Missing Y end right side number plate, 12/22. Has two 1990s ads inside, X end. Regional Measure 2 Demonstration Car.

362 - (Scrapped)

363 - (Scrapped) Regional Measure 2 Demonstration Car.

364 - (Scrapped)

365 - (Scrapped).One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car.

366 - (Scrapped) Zoho One Ad wrap.

367 - (Scrapped) Zoho One Ad wrap.

368 - (Scrapped)

369 - (Scrapped) Regional Measure 2 Demonstration Car.

370 - (Scrapped) Regional Measure 2 Demonstration Car.

371 - (Scrapped)

372 - (Scrapped) Smoke incident under car, Orinda, 10/23/2013. Scrapped.

373 - (Scrapped) Regional Measure 2 Demonstration Car.

374 - (Scrapped)

375 - (Scrapped)

352 - (Scrapped) Ex Zoho One Ad wrap. Regional Measure 2 Demonstration Car.

353 - (Scrapped)

354 - (Scrapped) One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car.

355 - (Scrapped)

356 - "Burrito Bob" incident car. Not listed on roster 5/23

357 - (Scrapped).One of final 2 dozen C1 cars.

358 - (Scrapped)

359 - (Scrapped)

360 - (Scrapped) Regional Measure 2 Demonstration Car.

361 - (Scrapped). One of final 2 dozen C1 cars. Active through 5/23. Missing Y end right side number plate, 12/22. Has two 1990s ads inside, X end. Regional Measure 2 Demonstration Car.

362 - (Scrapped)

363 - (Scrapped) Regional Measure 2 Demonstration Car.

364 - (Scrapped)

365 - (Scrapped).One of final 2 dozen C1 cars. Active until 5/23. Regional Measure 2 Demonstration Car.

366 - (Scrapped) Zoho One Ad wrap.

367 - (Scrapped) Zoho One Ad wrap.

368 - (Scrapped)

369 - (Scrapped) Regional Measure 2 Demonstration Car.

370 - (Scrapped) Regional Measure 2 Demonstration Car.

371 - (Scrapped)

372 - (Scrapped) Smoke incident under car, Orinda, 10/23/2013. Scrapped.

373 - (Scrapped) Regional Measure 2 Demonstration Car.

374 - (Scrapped)

375 - (Scrapped)

376-400

376 - (Scrapped). One of final 2 dozen C1 cars. Active as of 5/23

377 - (Scrapped)

378 - (Scrapped) Upside down 8 on exterior car number, X end

379 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23.

380 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23.

381 - (Scrapped). CB1 car. Zoho One Ad wrap.

382 - (Scrapped). Zoho One Ad wrap.

383 - (Scrapped)

384 - (Scrapped)

385 - (Scrapped)

386 - (Scrapped)

387 - Not listed on roster 5/23

388 - (Scrapped) "Dirty '88" - Grimy exterior (bad finishing?) for at least the past decade. Regional Measure 2 Demonstration Car.

389 - (Scrapped) CB1 car

390 - (Scrapped) Zoho One Ad wrap.

391 - (Scrapped) Dirty car, due to ad residue

392 - (Scrapped) Missing car number plate, replacement car number decals below pinstripes.

393 - (Scrapped)

394 - (Scrapped 5/19/23)

395 - Scrapped

396 - Scrapped Regional Measure 2 Demonstration Car.

397 - (Scrapped) Rear car of train involved in fatal accident on Oct 19, 2013. Regional Measure 2 Demonstration Car.

398 - (Scrapped) Regional Measure 2 Demonstration Car.

399 - (Scrapped) Regional Measure 2 Demonstration Car.

377 - (Scrapped)

378 - (Scrapped) Upside down 8 on exterior car number, X end

379 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23.

380 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23.

381 - (Scrapped). CB1 car. Zoho One Ad wrap.

382 - (Scrapped). Zoho One Ad wrap.

383 - (Scrapped)

384 - (Scrapped)

385 - (Scrapped)

386 - (Scrapped)

387 - Not listed on roster 5/23

388 - (Scrapped) "Dirty '88" - Grimy exterior (bad finishing?) for at least the past decade. Regional Measure 2 Demonstration Car.

389 - (Scrapped) CB1 car

390 - (Scrapped) Zoho One Ad wrap.

391 - (Scrapped) Dirty car, due to ad residue

392 - (Scrapped) Missing car number plate, replacement car number decals below pinstripes.

393 - (Scrapped)

394 - (Scrapped 5/19/23)

395 - Scrapped

396 - Scrapped Regional Measure 2 Demonstration Car.

397 - (Scrapped) Rear car of train involved in fatal accident on Oct 19, 2013. Regional Measure 2 Demonstration Car.

398 - (Scrapped) Regional Measure 2 Demonstration Car.

399 - (Scrapped) Regional Measure 2 Demonstration Car.

401-425

400 - (Scrapped)

401 - (Scrapped)

402 - (Scrapped) One of final 2 dozen C1 cars. Regional Measure 2 Demonstration Car.

403 - (Scrapped)

404 - (Scrapped) Error: car not found

405 - (Scrapped)

406 - (Scrapped) Regional Measure 2 Demonstration Car.

407 - (Scrapped)

408 - (Scrapped) Regional Measure 2 Demonstration Car.

409 - (Scrapped)

410 - (Scrapped) Regional Measure 2 Demonstration Car.

411 - (Scrapped)

412 - (Scrapped)

413 - (Scrapped)

414 - (Scrapped)

415 - (Scrapped)

416 - (Scrapped) Car number seen in Predator 2. Regional Measure 2 Demonstration Car.

417 - (Scrapped) One of final 2 dozen C1 cars. Active through of 4/23 Zoho One Ad wrap, remaining as of 4/23.

418 - (Scrapped) Zaytoven Presents Fo 15 Ad wrap.

419 - (Scrapped)

420 - (Scrapped) Regional Measure 2 Demonstration Car.

421 - (Scrapped) One of final 2 dozen C1 cars. Ex Zoho One Ad wrap.

422 - (Scrapped) Regional Measure 2 Demonstration Car.

423 - (Scrapped) Regional Measure 2 Demonstration Car.

424 - (Scrapped) One of final 2 dozen C1 cars. Active through 3/23

425 - (Scrapped)

401 - (Scrapped)

402 - (Scrapped) One of final 2 dozen C1 cars. Regional Measure 2 Demonstration Car.

403 - (Scrapped)

404 - (Scrapped) Error: car not found

405 - (Scrapped)

406 - (Scrapped) Regional Measure 2 Demonstration Car.

407 - (Scrapped)

408 - (Scrapped) Regional Measure 2 Demonstration Car.

409 - (Scrapped)

410 - (Scrapped) Regional Measure 2 Demonstration Car.

411 - (Scrapped)

412 - (Scrapped)

413 - (Scrapped)

414 - (Scrapped)

415 - (Scrapped)

416 - (Scrapped) Car number seen in Predator 2. Regional Measure 2 Demonstration Car.

417 - (Scrapped) One of final 2 dozen C1 cars. Active through of 4/23 Zoho One Ad wrap, remaining as of 4/23.

418 - (Scrapped) Zaytoven Presents Fo 15 Ad wrap.

419 - (Scrapped)

420 - (Scrapped) Regional Measure 2 Demonstration Car.

421 - (Scrapped) One of final 2 dozen C1 cars. Ex Zoho One Ad wrap.

422 - (Scrapped) Regional Measure 2 Demonstration Car.

423 - (Scrapped) Regional Measure 2 Demonstration Car.

424 - (Scrapped) One of final 2 dozen C1 cars. Active through 3/23

425 - (Scrapped)

426-450

426 - (Scrapped) Regional Measure 2 Demonstration Car.

427 - (Scrapped) Kaiser Ad wrap. Regional Measure 2 Demonstration Car.

428 - (Scrapped) Regional Measure 2 Demonstration Car.

429 - (Scrapped) Regional Measure 2 Demonstration Car.

430 - (Scrapped) Regional Measure 2 Demonstration Car.

431 - (Scrapped) Zoho One Ad wrap. Regional Measure 2 Demonstration Car.

432 - (Scrapped) One of final 2 dozen C1 cars. Active until 5/23.

433 - (Scrapped)

434 - (Scrapped) Regional Measure 2 Demonstration Car.

435 - (Scrapped) Zoho One Ad wrap.

436 - (Scrapped)

437 - (Scrapped) Zoho One Ad wrap.

438 - (Scrapped) Regional Measure 2 Demonstration Car.

439 - (Scrapped) CB1 car. Regional Measure 2 Demonstration Car.

440 - (Scrapped). One of final 2 dozen C1 cars. Active through 4/23. Under floor cab exterior painted black 2/19, 4/23. Regional Measure 2 Demonstration Car.

441 - (Scrapped) Regional Measure 2 Demonstration Car.

442 - (Scrapped) Regional Measure 2 Demonstration Car.

443 - (Scrapped) Regional Measure 2 Demonstration Car.

444 - (Scrapped) Regional Measure 2 Demonstration Car.

445 - (Scrapped)

446 - (Scrapped)

447 - (Scrapped)

448 - (Scrapped)

449 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23.

450 - (Scrapped). On display at Colma groundbreaking. Regional Measure 2 Demonstration Car.

427 - (Scrapped) Kaiser Ad wrap. Regional Measure 2 Demonstration Car.

428 - (Scrapped) Regional Measure 2 Demonstration Car.

429 - (Scrapped) Regional Measure 2 Demonstration Car.

430 - (Scrapped) Regional Measure 2 Demonstration Car.

431 - (Scrapped) Zoho One Ad wrap. Regional Measure 2 Demonstration Car.

432 - (Scrapped) One of final 2 dozen C1 cars. Active until 5/23.

433 - (Scrapped)

434 - (Scrapped) Regional Measure 2 Demonstration Car.

435 - (Scrapped) Zoho One Ad wrap.

436 - (Scrapped)

437 - (Scrapped) Zoho One Ad wrap.

438 - (Scrapped) Regional Measure 2 Demonstration Car.

439 - (Scrapped) CB1 car. Regional Measure 2 Demonstration Car.

440 - (Scrapped). One of final 2 dozen C1 cars. Active through 4/23. Under floor cab exterior painted black 2/19, 4/23. Regional Measure 2 Demonstration Car.

441 - (Scrapped) Regional Measure 2 Demonstration Car.

442 - (Scrapped) Regional Measure 2 Demonstration Car.

443 - (Scrapped) Regional Measure 2 Demonstration Car.

444 - (Scrapped) Regional Measure 2 Demonstration Car.

445 - (Scrapped)

446 - (Scrapped)

447 - (Scrapped)

448 - (Scrapped)

449 - (Scrapped). One of final 2 dozen C1 cars. Active until 5/23.

450 - (Scrapped). On display at Colma groundbreaking. Regional Measure 2 Demonstration Car.

Last updated 3/27/24

November 2022 active cars spotted: 20/40

December 2022 active cars spotted: 16/40

January 2023 active cars spotted: 19/32

April 2023 active cars spotted: 17/24

May 2023 active cars spotted: 15/24

June 2023 active cars: 0

November 2022 active cars spotted: 20/40

December 2022 active cars spotted: 16/40

January 2023 active cars spotted: 19/32

April 2023 active cars spotted: 17/24

May 2023 active cars spotted: 15/24

June 2023 active cars: 0