Background

|

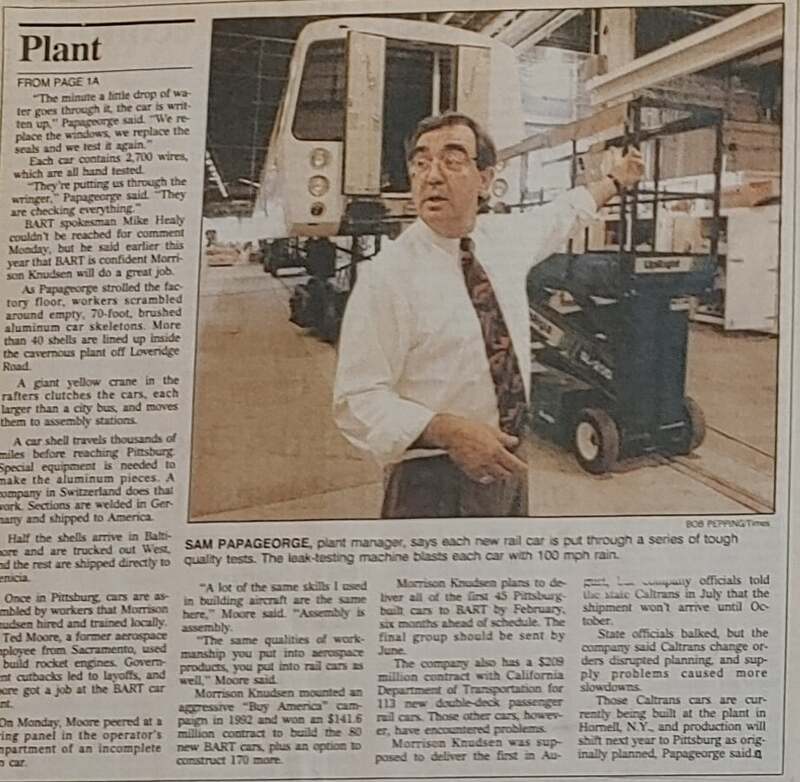

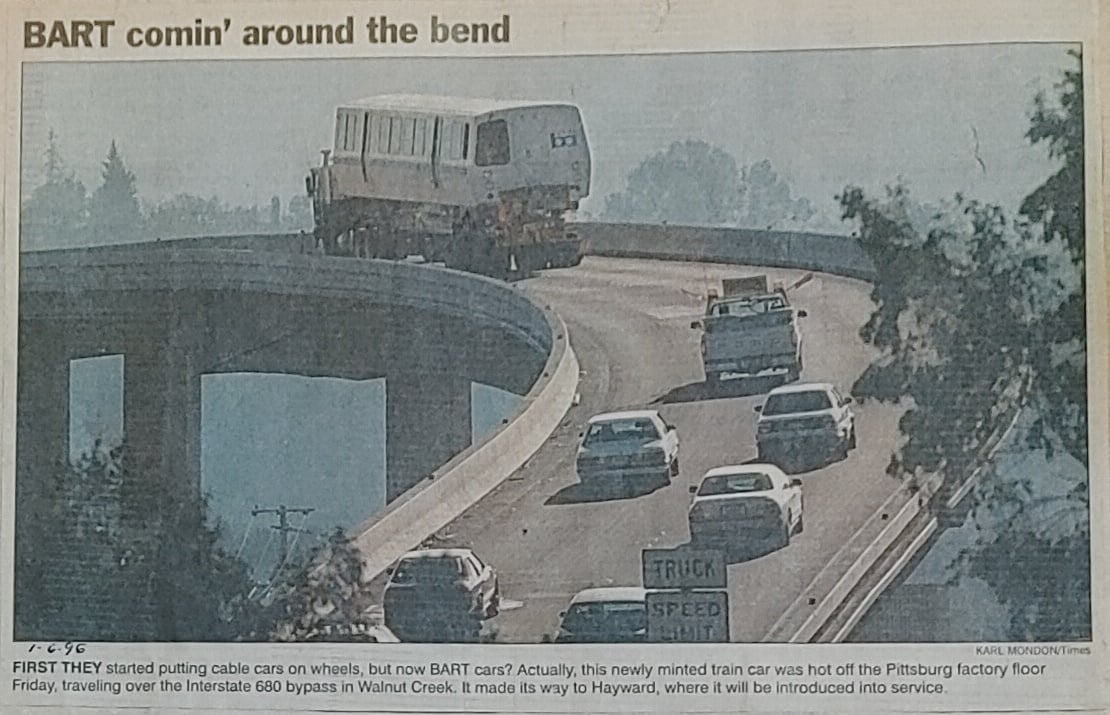

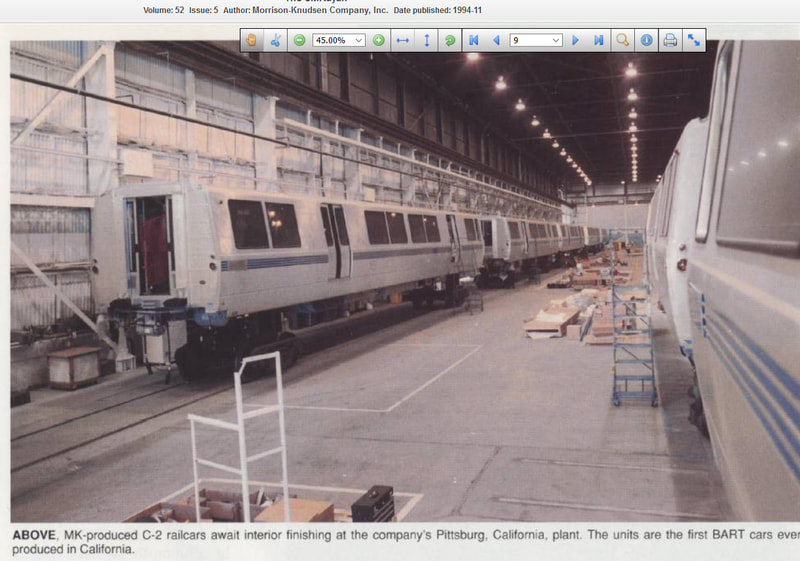

The second order C cars, the C2 cars, were ordered in 1992, at a cost of roughly $1.7 million per car (financed locally), and entered revenue service in 1995 and 1996. They were built by Morrison-Knudsen. Car shells were sourced from Germany, and final assembly was at Hornell (first 5 cars) and Pittsburg, CA (following 75 cars). My understanding is that this facility (formerly the US Steel Plant) is now used to build the new BART Fleet of the Future cars.

The delivery of these cars helped provide service to the new expansions of the system: Pittsburg/Bay Point (1996), and Dublin/Pleasanton (1997). By the late 2010s, their main home yards were mainly Concord and Hayward, and ran on the Yellow line, Green line, and Blue line, generally speaking. |

|

|

As a whole, these cars were regarded as the least reliable and most problematic car type. One measure of reliability the Mean Time Between Incident showed that the C2 cars had the lowest of the fleet - 112 hours for C2 cars, compared to 153 hours for A2 cars, about 370 hours for B2 cars, 161 hours for C1 cars.

They reached their end with the COVID-19 pandemic (with reduced service requiring fewer cars). They were stored, for good, across the system starting around May/June 2020. A train of roughly 8-9 of them was seen testing shortly before the opening of Berryessa and Milpitas, and a few were out in service, briefly, in June 2020. Scrapping wise, 2528 was the first to go in November 2019. After storage across the system and one-by-one scrapping, the final C2 car, 2558, was scrapped in August 2021. |

|

They were extremely similar to the Alstom built C1 cars (Fleet no 301-450) that preceded them. For general infomation on the C car design, see: C1 cars. There were many minor differences from the C1s, and at the end, the most visible contrast was the interior (seats/armrest were different in paneling, alongside the red ADA lights on the windscreen railing), minor mechanical changes, and cab details. They were the bread and butter for the Green Line, alongside a large presence on the Blue line and usually midtrain on the Yellow Line (Hayward and Concord yards).

They used the Westinghouse 1463 motor with chopper control, the same type used on BART since the early days. Thus, they had the characteristic buzzing/humming during acceleration and braking, akin to the C1 cars still rolling today. |

General Details

|

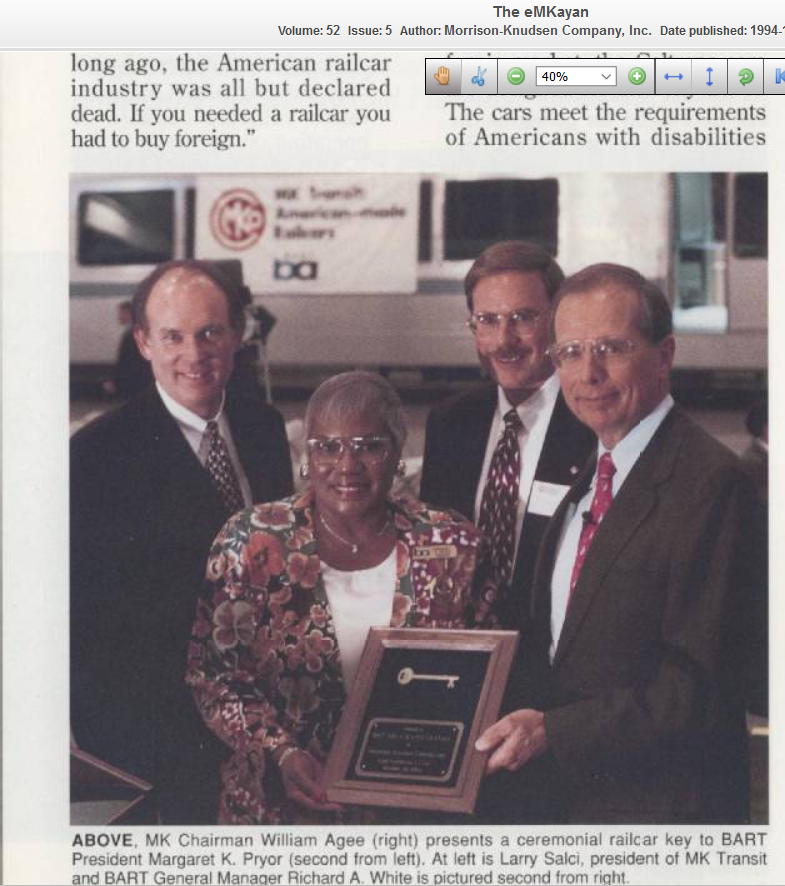

Builder: Morrison-Knudsen

Original Assembly Location: Hornell, NY (First 5 cars), Pittsburg, CA (Remaining 75) Years of Construction: 1994-1996 Quantity: 80 Length: 70 feet Weight (Empty): 63,500-64,100 lbs Seats: 69 (original), 56 (last) Propulsion: Westinghouse DC Chopper drive with 4 x 150 HP Westinghouse Model 1463 motors Brakes: Knorr dynamic/regenerative to 3 mph, Hydraulic friction braking below 3 mph. Auxiliary Power Supply Equipment (APSE): GE HVAC: Wabco, 14 ton Truck: Fabricated Steel or Cast Steel Electronic Horn: Federal Signal Coupler: Wabco N3 Preventative Maintenance: Every 600 hours Cost: $141.6 Million Avg mileage: 2.4 Million miles |

Construction

Some newspaper clippings on the early days of the Morrison-Knudsen built C2 cars (in service from 1995-2020).

Newspaper clippigns are art of the Therkelson Collection, Prelinger Library, and the pictures are part of the Western Railway Museum Archives. The digital scans are from a virtual collection of the MKayan magazine.

The car bodies were built in the Linke-Hofmann-Busch plant in Salzgitter, Germany.

Click on each photo for more details.

Newspaper clippigns are art of the Therkelson Collection, Prelinger Library, and the pictures are part of the Western Railway Museum Archives. The digital scans are from a virtual collection of the MKayan magazine.

The car bodies were built in the Linke-Hofmann-Busch plant in Salzgitter, Germany.

Click on each photo for more details.

C1 vs C2

There were very minor differences between the C1 and C2 cars. Early on, the C2s featured flip-up seats (similar to eBART) in the ADA space. Minor differences existed in the operator console and other parts of the cab, plus some mechanical changes from the C1 cars. By the late 2010s, the most visible contrast to the riding public was the interior (seats/armrest were different in design (Wilson Art beige millstone aluminum/melamine pattern on C2s instead of the imitation teak wood on the C1s), alongside the red ADA lights on the windscreen railing). Certain C2 cars had blue floors in an experiment to gauge public opinion for the floor color of the Fleet of the Future.

Click the photo gallery to view captions.

Click the photo gallery to view captions.

CB2 (and CB1) Cars

A few C2 cars, and some C1 cars, were converted into essentially B cars. The lack of fully functioning ATO equipment, and other equipment in some cases, resulted these cars only running midtrain during revenue service. They retained their C car propulsion package and seating. See all CB Cars here.

Click on each photo for the full size image.

Click on each photo for the full size image.

Scrapping

The C2 cars were scrapped in Oakland, CA from 2019 to 2021.

Click on each photo for the full size image.

Click on each photo for the full size image.

Car-by-car Roster Photos

Click on each photo for more details.

2501-2525

2501 - Built 8/1994, in Hornell, NY

2502 - Built in in Hornell, NY. Regional Measure 2 Demonstration Car.

2503 - Built in in Hornell, NY. Regional Measure 2 Demonstration Car.

2504 - Built in in Hornell, NY. Regional Measure 2 Demonstration Car.

2505 - Built in in Hornell, NY. CB2 Car

2506 - Regional Measure 2 Demonstration Car.

2507 - CB2 Car. Regional Measure 2 Demonstration Car.

2508

2509 - CB2 Car. Regional Measure 2 Demonstration Car.

2510 - Regional Measure 2 Demonstration Car.

2511 - Regional Measure 2 Demonstration Car.

2512 - Regional Measure 2 Demonstration Car.

2513 - Regional Measure 2 Demonstration Car.

2514 - Regional Measure 2 Demonstration Car.

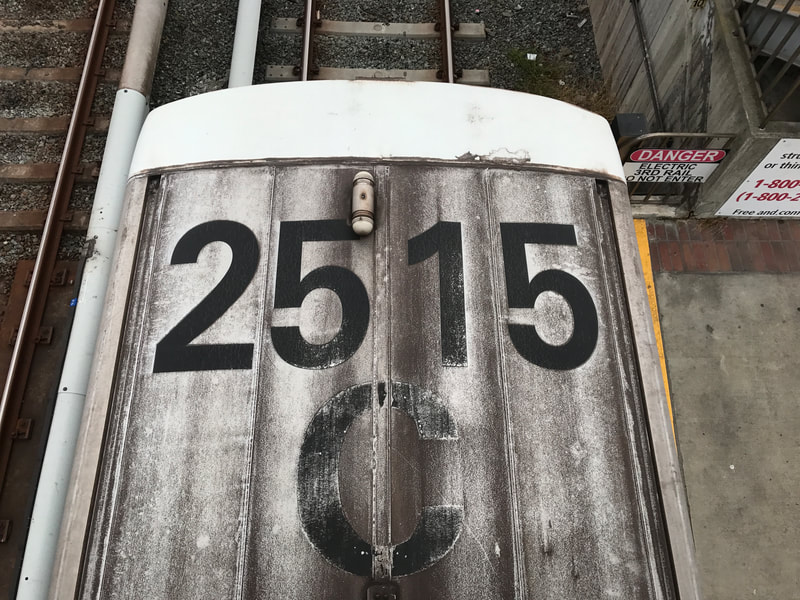

2515 - Regional Measure 2 Demonstration Car.

2516 - Extremely heavy Y end front white paint chipping, (due to wash rack acidity) since 2008. Regional Measure 2 Demonstration Car.

2517 - Regional Measure 2 Demonstration Car.

2518 - Regional Measure 2 Demonstration Car.

2519

2520 - Regional Measure 2 Demonstration Car.

2521 - Regional Measure 2 Demonstration Car.

2522 - Regional Measure 2 Demonstration Car.

2523 - Regional Measure 2 Demonstration Car.

2524 - Y end front white paint chipping. Regional Measure 2 Demonstration Car.

2525 - Regional Measure 2 Demonstration Car.

2502 - Built in in Hornell, NY. Regional Measure 2 Demonstration Car.

2503 - Built in in Hornell, NY. Regional Measure 2 Demonstration Car.

2504 - Built in in Hornell, NY. Regional Measure 2 Demonstration Car.

2505 - Built in in Hornell, NY. CB2 Car

2506 - Regional Measure 2 Demonstration Car.

2507 - CB2 Car. Regional Measure 2 Demonstration Car.

2508

2509 - CB2 Car. Regional Measure 2 Demonstration Car.

2510 - Regional Measure 2 Demonstration Car.

2511 - Regional Measure 2 Demonstration Car.

2512 - Regional Measure 2 Demonstration Car.

2513 - Regional Measure 2 Demonstration Car.

2514 - Regional Measure 2 Demonstration Car.

2515 - Regional Measure 2 Demonstration Car.

2516 - Extremely heavy Y end front white paint chipping, (due to wash rack acidity) since 2008. Regional Measure 2 Demonstration Car.

2517 - Regional Measure 2 Demonstration Car.

2518 - Regional Measure 2 Demonstration Car.

2519

2520 - Regional Measure 2 Demonstration Car.

2521 - Regional Measure 2 Demonstration Car.

2522 - Regional Measure 2 Demonstration Car.

2523 - Regional Measure 2 Demonstration Car.

2524 - Y end front white paint chipping. Regional Measure 2 Demonstration Car.

2525 - Regional Measure 2 Demonstration Car.

2526-2550

2526 - Regional Measure 2 Demonstration Car.

2527 - Low intercar door sticker. Regional Measure 2 Demonstration Car.

2528 - Lead car of train involved in fatal accident on Oct 19, 13. Stored at Hayward yard c.2019. First revenue car to be officially retired (of the 669 car count), Nov 8, 2019. Regional Measure 2 Demonstration Car.

2529

2530 - Regional Measure 2 Demonstration Car.

2531 - Regional Measure 2 Demonstration Car.

2532 - Cab hinge window mod Demonstration car. Regional Measure 2 Demonstration Car.

2533 - Regional Measure 2 Demonstration Car.

2534

2535 - Regional Measure 2 Demonstration Car.

2536 - Regional Measure 2 Demonstration Car.

2537

2538 - Regional Measure 2 Demonstration Car.

2539 - Experimental BT-3 tapered wheel profile car. Scrapped 1/31/20. Regional Measure 2 Demonstration Car.

2540 - Regional Measure 2 Demonstration Car.

2541

2542

2543 - CB2 Car. Regional Measure 2 Demonstration Car.

2544 - Regional Measure 2 Demonstration Car.

2545 - Regional Measure 2 Demonstration Car.

2546

2547 - Hard braking during station program stop. Regional Measure 2 Demonstration Car.

2548

2549 - Regional Measure 2 Demonstration Car.

2550 - Lowest MBTI of C2 cars. Regional Measure 2 Demonstration Car.

2527 - Low intercar door sticker. Regional Measure 2 Demonstration Car.

2528 - Lead car of train involved in fatal accident on Oct 19, 13. Stored at Hayward yard c.2019. First revenue car to be officially retired (of the 669 car count), Nov 8, 2019. Regional Measure 2 Demonstration Car.

2529

2530 - Regional Measure 2 Demonstration Car.

2531 - Regional Measure 2 Demonstration Car.

2532 - Cab hinge window mod Demonstration car. Regional Measure 2 Demonstration Car.

2533 - Regional Measure 2 Demonstration Car.

2534

2535 - Regional Measure 2 Demonstration Car.

2536 - Regional Measure 2 Demonstration Car.

2537

2538 - Regional Measure 2 Demonstration Car.

2539 - Experimental BT-3 tapered wheel profile car. Scrapped 1/31/20. Regional Measure 2 Demonstration Car.

2540 - Regional Measure 2 Demonstration Car.

2541

2542

2543 - CB2 Car. Regional Measure 2 Demonstration Car.

2544 - Regional Measure 2 Demonstration Car.

2545 - Regional Measure 2 Demonstration Car.

2546

2547 - Hard braking during station program stop. Regional Measure 2 Demonstration Car.

2548

2549 - Regional Measure 2 Demonstration Car.

2550 - Lowest MBTI of C2 cars. Regional Measure 2 Demonstration Car.

2551-2580

2551

2552 - Regional Measure 2 Demonstration Car.

2553 - Regional Measure 2 Demonstration Car.

2554 - Regional Measure 2 Demonstration Car.

2555 - Regional Measure 2 Demonstration Car.

2556 - Stored in Deadline at Hayward Yard, 2019. CB2 Car. Regional Measure 2 Demonstration Car.

2557 - Regional Measure 2 Demonstration Car.

2558 - Regional Measure 2 Demonstration Car.

2559 - Regional Measure 2 Demonstration Car.

2560

2561 - Regional Measure 2 Demonstration Car.

2562

2563 - Regional Measure 2 Demonstration Car.

2564

2565

2566 - Regional Measure 2 Demonstration Car.

2567 - Regional Measure 2 Demonstration Car.

2568 - Regional Measure 2 Demonstration Car.

2569

2570

2571 - Seen in "Nash Bridges" Night Train (TV Episode 1996). Regional Measure 2 Demonstration Car.

2572 - Regional Measure 2 Demonstration Car.

2573 - Seen in "Nash Bridges" Night Train (TV Episode 1996) Regional Measure 2 Demonstration Car.

2574 - Used as Hayward Test Track car after A car 164 (temporary). Regional Measure 2 Demonstration Car.

2575 - Seen in "Nash Bridges" Night Train (TV Episode 1996). Regional Measure 2 Demonstration Car.

2576 - Regional Measure 2 Demonstration Car.

2577 - Regional Measure 2 Demonstration Car.

2578 - Regional Measure 2 Demonstration Car.

2579

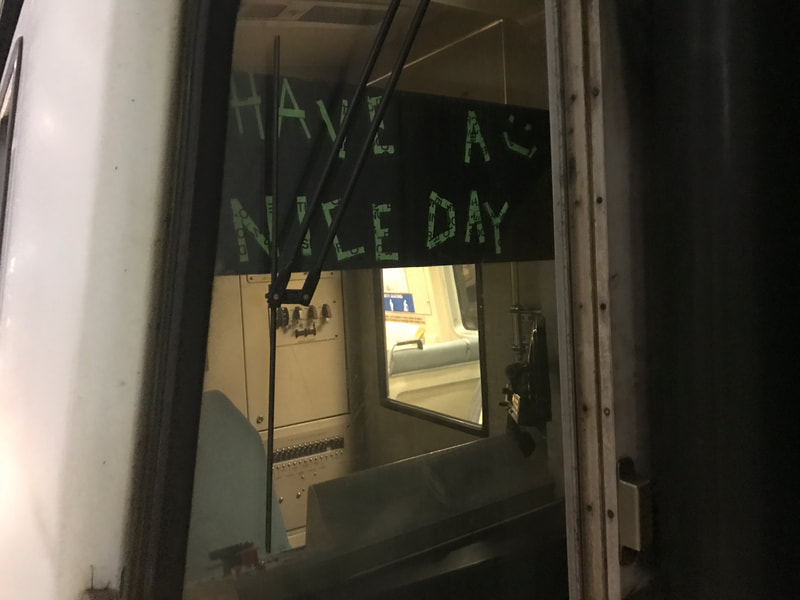

2580 - Last BART revenue car built for 20 years. "Have a Nice Day" on sunshade. Regional Measure 2 Demonstration Car. Likely final rapid transit car built by an American company for an American rapid transit system.

2552 - Regional Measure 2 Demonstration Car.

2553 - Regional Measure 2 Demonstration Car.

2554 - Regional Measure 2 Demonstration Car.

2555 - Regional Measure 2 Demonstration Car.

2556 - Stored in Deadline at Hayward Yard, 2019. CB2 Car. Regional Measure 2 Demonstration Car.

2557 - Regional Measure 2 Demonstration Car.

2558 - Regional Measure 2 Demonstration Car.

2559 - Regional Measure 2 Demonstration Car.

2560

2561 - Regional Measure 2 Demonstration Car.

2562

2563 - Regional Measure 2 Demonstration Car.

2564

2565

2566 - Regional Measure 2 Demonstration Car.

2567 - Regional Measure 2 Demonstration Car.

2568 - Regional Measure 2 Demonstration Car.

2569

2570

2571 - Seen in "Nash Bridges" Night Train (TV Episode 1996). Regional Measure 2 Demonstration Car.

2572 - Regional Measure 2 Demonstration Car.

2573 - Seen in "Nash Bridges" Night Train (TV Episode 1996) Regional Measure 2 Demonstration Car.

2574 - Used as Hayward Test Track car after A car 164 (temporary). Regional Measure 2 Demonstration Car.

2575 - Seen in "Nash Bridges" Night Train (TV Episode 1996). Regional Measure 2 Demonstration Car.

2576 - Regional Measure 2 Demonstration Car.

2577 - Regional Measure 2 Demonstration Car.

2578 - Regional Measure 2 Demonstration Car.

2579

2580 - Last BART revenue car built for 20 years. "Have a Nice Day" on sunshade. Regional Measure 2 Demonstration Car. Likely final rapid transit car built by an American company for an American rapid transit system.

Updated: 6/7/23, 6/2/23. 6/30/22, 10/1/22, 10/16/22, 2/16/24